Juice Filling Equipment Line

Juice filling equipment from a trusted manufacturer—enhance productivity, reduce expenses, and enjoy full-line customization and service.

This Juice Filling Equipment integrates washing filling and capping into one unit, it can be used for hot-filling production of different kinds of fruit juice and tea drinks.

Juice Filling Equipment Features

1.High Precision &Compliance

Advanced PLC controls and servo-driven filling mechanisms guarantee accuracy (±1% error) and consistent output, minimizing waste and maximizing efficiency.

2.Versatility in Applications

Adaptable to a wide range of container types, including bottles, cans, and pouches, as well as different juice viscosities such as clear, pulpy, or NFC juices, featuring quick-changeover systems for efficient transitions between products.

3.Sustainable & Energy-Efficient

Low-resource consumption, compatibility with eco-friendly packaging, and energy-saving technologies (e.g., heat recovery in hot-fill processes).

4.Muti-Layer Sealing & Automation

Supports nitrogen flushing or vacuum sealing options to extend shelf life by reducing oxidation, ideal for premium or organic juices requiring minimal preservatives.

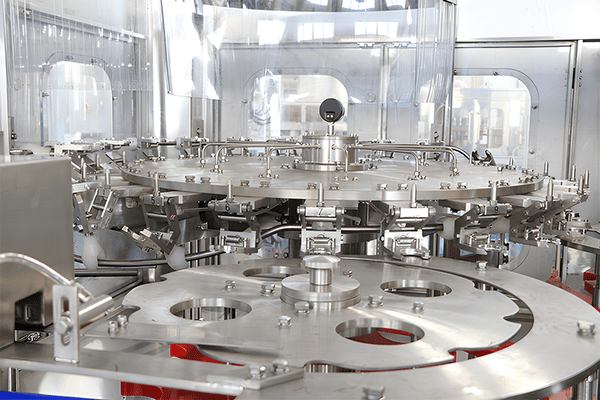

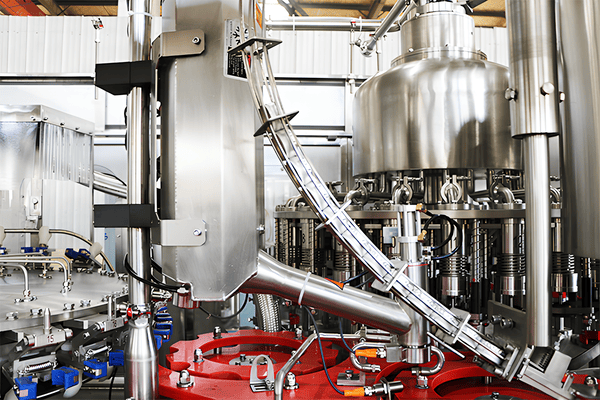

Detailed Photos Of Juice Filling Equipment

Industry -Specific Attributes

| Project Name:Juice Filling Machine | |||||||||

| Model | RCGF8-8-4 | RCGF14-12-5 | RCGF16-16-5 | RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-8/10 | RCGF40-40-10 | RCGF50-50-15 | RCGF60-60-20 |

| Washing Heads | 8 | 14 | 16 | 18 | 24 | 32 | 40 | 50 | 60 |

| Filling Heads | 8 | 12 | 16 | 18 | 24 | 32 | 40 | 50 | 60 |

| Capping Heads | 4 | 5 | 5 | 6 | 8 | 8/10 | 10 | 15 | 20 |

| Capacity(BPH) | 1500 | 2000 | 3000 | 4500 | 8000 | 10000 | 12000 | 15000 | 20000 |

| Suitable Bottle | Plastic/Glass | ||||||||

| Filling Range | 0.2-2L | ||||||||

| Filling temperature |

80-90℃ |

||||||||

| Weight(KG) | 1000-8000kg |

||||||||

| After-sales Service | Video technical support, Field installation, commissioning and training, Online support, Field maintenance and repair service, Free spare parts | ||||||||

Leave A Message

Please fill your detailed contact info to get better service from us

What Is a Juice Production Line and How Does It Work?

Why Is a Complete Juice Production Line Important for Beverage Manufacturers?

How to Choose the Right Juice Production Line for Your Business?

Where Can a Juice Production Line Be Installed and What Conditions Are Required?

How Much Does a Juice Production Line Cost and What Factors Affect the Price?

Best Reason For Choose Our Service

Automate More Stuff Relax More.

24x7 Hours Customer Support

Trusted By Leaders Valuable Ideas

Keeping You in Touch With Your Customers.

Get the latest to your inbox

Never miss out on technology news, insights, and more with our newsletter.