Description

9000BPH Automatic OPP Hot Melt Labeling Machine

Product Description

| Hot glue opp labeling machine | ||

| NO | Item | Parameter data |

| 1 | Voltage | 380V |

| 2 | Frequency | 50Hz |

| 3 | Power | 8KW |

| 4 | Available bottle dimension | Diameter:40-105mm, |

| height=80-350MM | ||

| 5 | Label specification | Length:125-325mm, |

| Height:20-150mm | ||

| 6 | Gluing way | Roll painting(about 10mm, both label head and tail) |

| 7 | Capacity | 9000-36000 bottles per hour |

| (500ml bottle) | ||

| 8 | Glue Consumption | l kg/ 100,000bolttle |

| (label height:50mm) | ||

| 9 | Compressed Air Pressure | MIN5.0bar MAX8.0bar |

| 10 | Consumption of Compressed Air | 0.2M3/minute |

| 11 | Overall dimension | 2500Kg |

| 12 | Total Weight | L=3150,W=1770,H=1800 |

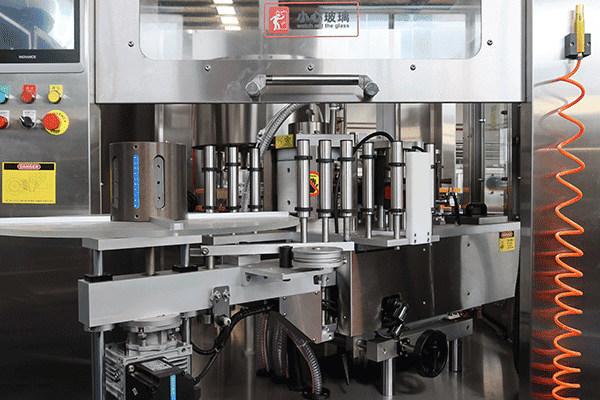

Feeding Star Wheel

The feeding star wheel is responsible for transferring bottles from the conveyor to the labeling station with high precision. OPP labeling machine synchronizes with the main labeling drum and other mechanical components to ensure smooth bottle handling and accurate positioning. The star wheel is made from wear-resistant materials and precisely machined to match specific bottle shapes and sizes, minimizing vibration and bottle damage during high-speed operation.

Bottle Feeding Screw

The bottle feeding screw (also known as the timing screw) aligns and spaces bottles uniformly as they move toward the star wheel. It ensures proper bottle orientation and consistent intervals, preventing collisions or misfeeds. By guiding bottles smoothly and steadily, the feeding screw helps optimize the labeling accuracy and supports high-speed, continuous production without disruption.

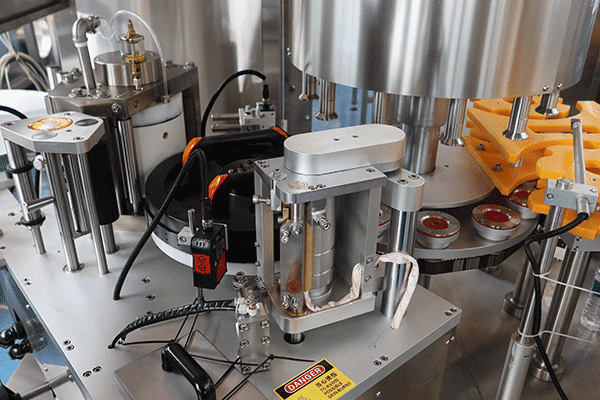

Glue Feeder

The glue feeder system precisely applies hot melt adhesive to the label edges or specific contact points. It uses a heated tank and pump to maintain the glue at a stable temperature and viscosity, ensuring consistent flow. The nozzle applies glue in thin, controlled patterns, reducing adhesive waste while maintaining strong adhesion. This system is designed for easy cleaning and maintenance, improving operational efficiency and product quality.

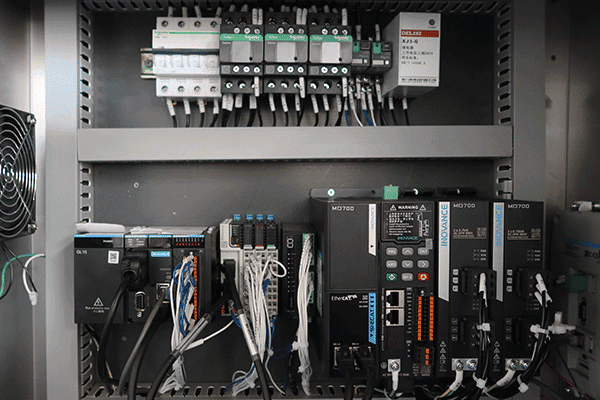

Electricity Unit

The electricity unit houses the main control system, including the PLC, inverter, temperature controller, and touch screen interface. It provides centralized and intelligent control over all labeling processes—such as bottle detection, glue application, motor speed, and safety alarms. OPP labeling machine with user-friendly operation and fault diagnostics, the electrical system ensures stable performance, easy parameter adjustments, and rapid troubleshooting to minimize downtime.

Why Choose Us

Direct Manufacturer: With over 10 years of experience in developing and manufacturing beverage and liquid food filling machines. Our plant spans 4000m², and we have independent property rights.

Professional Export Team: We offer stable product quality, fast delivery, and clear communication, ensuring smooth international transactions.

Custom Manufacturing: Our skilled technical team can design machines in various sizes and configurations to meet your unique specifications.

Strict Quality Control: We never ship equipment without customer approval. Every machine undergoes 24-hour testing before shipping, and we ensure quality is controlled at every production stage.

12-Month Warranty: All our equipment comes with a 12-month warranty, and we provide lifetime technical support for all products.

Fast Spare Parts Availability: We supply spare parts quickly and at cost price, minimizing downtime and ensuring operational continuity.