Description

9000BPH Automatic Bottle Plastic Bottle Sleeve Labeling Machine

Product Description

| Sleeve Labeling Machine | ||

| 1 | Production capacity | 1000-9000 bottles/hour |

| 2 | Input power | 3.5kw |

| 3 | Input voltage | 220V AC |

| 4 | Size of host machine (L*W*H) | 2000*950*1950mm |

| 5 | Weight | 750kg |

| 6 | Applicable diameter of bottle body | φ28 mm-φ100 mm |

| 7 | plicable length of label | 30 mm-220 mm |

| 8 | Applicable thickness of label | 0.03 mm-0.13 mm |

| 9 | Applicable internal diameter of paper tube | 5″-10 “free adjustment |

Automatic Sleeve Applicator

The automatic sleeve applicator accurately places shrink sleeves onto bottles or containers at high speed. Sleeve labeling machine is equipped with a servo-controlled system for precise label positioning, ensuring consistent and wrinkle-free application. This system handles a variety of container shapes and sizes, supporting flexible production and seamless integration into different packaging lines.

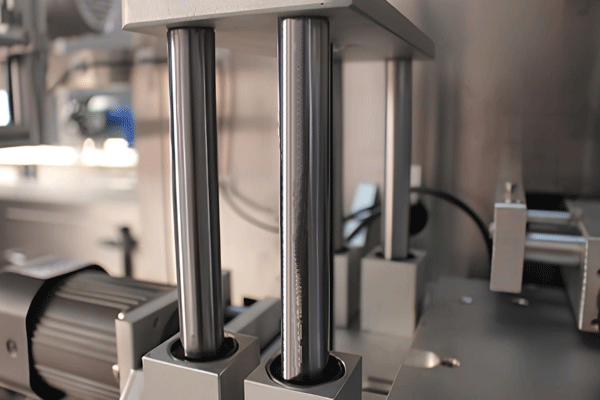

Slap Label Device (Prevent Labels from Tilting)

The slap label device ensures the label is firmly and evenly attached to the container before heat shrinking. It effectively prevents label tilting, shifting, or misalignment by gently pressing the label into position. This mechanism plays a critical role in maintaining labeling precision, especially at high speeds or with irregularly shaped bottles.

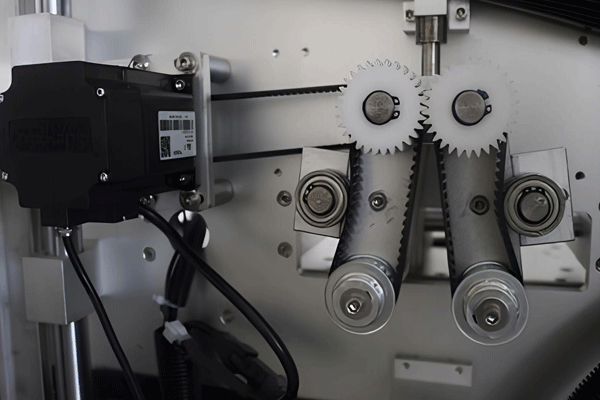

Electrical Components

The steam shrinking furnace uses evenly distributed, high-temperature steam to shrink the sleeve tightly around the container. Its stainless-steel chamber is corrosion-resistant and insulated for energy efficiency. Sleeve labeling machine with adjustable nozzles and zone control, it ensures uniform shrinkage without damaging the label or container, resulting in a clean, professional finish.

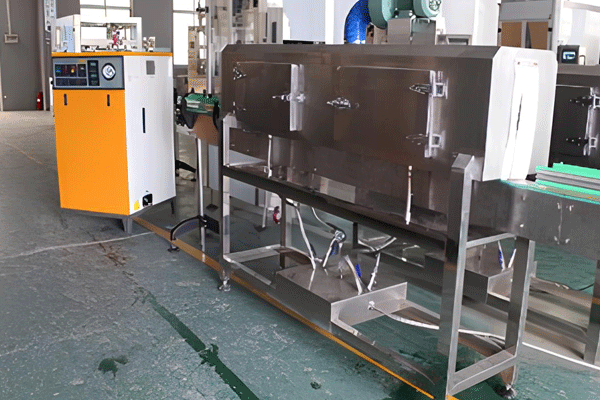

Steam Shrinking Furnace

The steam shrinking furnace uses evenly distributed, high-temperature steam to shrink the sleeve tightly around the container. Its stainless-steel chamber is corrosion-resistant and insulated for energy efficiency. With adjustable nozzles and zone control, it ensures uniform shrinkage without damaging the label or container, resulting in a clean, professional finish.

Why Choose Us

Direct Manufacturer: With over 10 years of experience in developing and manufacturing beverage and liquid food filling machines. Our plant spans 4000m², and we have independent property rights.

Professional Export Team: We offer stable product quality, fast delivery, and clear communication, ensuring smooth international transactions.

Custom Manufacturing: Our skilled technical team can design machines in various sizes and configurations to meet your unique specifications.

Strict Quality Control: We never ship equipment without customer approval. Every machine undergoes 24-hour testing before shipping, and we ensure quality is controlled at every production stage.

12-Month Warranty: All our equipment comes with a 12-month warranty, and we provide lifetime technical support for all products.

Fast Spare Parts Availability: We supply spare parts quickly and at cost price, minimizing downtime and ensuring operational continuity.