Description

DCGF14-12-5 700BPH 2000ML Large Bottle Carbonated Drink Filling Machine

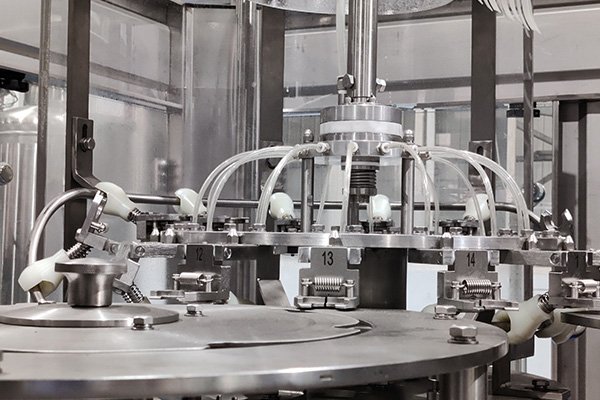

DCGF14-12-5 Filling Machine

Large Bottle DCGF14-12-5 Filling Machine

| Feature | Standard sokos carbonated drink filling machine | Large-Bottle sokos carbonated drink filling machine |

|---|---|---|

| Production Capacity | 2,500 BPH | 700 BPH |

| Bottle Size Range | 300-1000ml | 2000-3000ml |

| Rinse Heads | 14 | 14 |

| Filling Heads | 12 | 12 |

| Capping Heads | 5 | 5 |

| CO₂ Retention | ±0.1 vol | ±0.15 vol |

| Filling Accuracy | ±1% of volume | ±1.5% of volume |

| Conveyor Height | 850mm | 1100mm |

| Machine Footprint | 3.2m × 2.1m | 3.5m × 2.3m |

| Changeover Time | 10 minutes | 15 minutes |

| Power Consumption | 15kW | 18kW |

Technical Notes for Large-Bottle

Specialized low-pressure filling valves

Reinforced bottle grippers for heavy containers

Extended dwell time for foam dissipation

Optional nitrogen pre-purge for oxygen-sensitive products

Rinsing System (14 Heads)

Core Technology:

14-station rotary rinsing with Ø12-20mm adjustable nozzles

Triple-stage cleaning:

① 2.5Bar reverse pre-wash → ② 5Bar sterile water blast → ③ 0.5Bar air knife dryingAnti-tip bottle grippers: Pneumatic clamping secures heavy bottles during washing

Key Advantages:

✔ Residual water ≤0.3ml

✔ Crack detection (0.2mm accuracy) via infrared sensors

✔ 40% water savings with UV-sanitized recirculation system

Filling System (12 Heads)

Innovation Highlights:

Low-pressure valves (0.8-1.2Bar) prevent bottle stress/explosions

Dual-phase filling technology:

▸ Phase 1: CO₂ pre-pressurization

▸ Phase 2: Controlled liquid fillingReal-time weight compensation: Load cells ensure ±1.5% volume accuracy

Performance Data:

✔ 700BPH at 3000ml fill volume

✔ CO₂ loss ≤0.15vol

✔ 5-25℃ temperature range with glycol-cooled filling chamber

Capping System (15 Heads)

Precision Engineering:

Heavy-duty capping heads: 12N·m max torque

Dual safety checks:

① Metal detector

② Torque monitoringSelf-centering chucks: Servo-guided alignment for large bottle mouths

Quality Assurance:

✔ Leakage rate <0.02%

✔ Cap damage rate <0.1‰

✔ Cap orientation ≤1° deviation

Why Choose Us

Direct Manufacturer: With over 10 years of experience in developing and manufacturing beverage and liquid food filling machines. Our plant spans 4000m², and we have independent property rights.

Professional Export Team: We offer stable product quality, fast delivery, and clear communication, ensuring smooth international transactions.

Custom Manufacturing: Our skilled technical team can design machines in various sizes and configurations to meet your unique specifications.

Strict Quality Control: We never ship equipment without customer approval. Every machine undergoes 24-hour testing before shipping, and we ensure quality is controlled at every production stage.

12-Month Warranty: All our equipment comes with a 12-month warranty, and we provide lifetime technical support for all products.

Fast Spare Parts Availability: We supply spare parts quickly and at cost price, minimizing downtime and ensuring operational continuity.