Description

DGF 14-12-5 Soda Water Carbonated Beverage liquid filling bottling machine

Technical parameter : carbonated beverage production line

| Liquid Filling Bottling Machine Model | DCGF14-12-5 | ||

| Production capacity (bottles/hour) | 2000-2500/phb | ||

| Suitable bottle shape | PET round or square shape | ||

| Bottle diameter (millimeters) | Ф50-Ф 100mm | ||

| Bottle height (millimeters) | 50-320mm | ||

| Compressed air pressure (MPa) | 0.3-0.7Mpa | ||

| Washing medium | purified water | ||

| Washing water pressure (MPa) | >0.06Mpa <0.2Mpa | ||

| Total power (kW) | 3 | ||

| Overall dimensions (millimeters) | 2000x1500x2200 | ||

| Weight (kg) | 2000 | ||

Water Treatment

Tailored Water Treatment Solutions

We analyze your:

• Source water test reports

• Target water quality requirements

…to specify the optimal treatment system for your unique needs.

Beverage Mixing System

✓ High-Precision Mixing Performance

Consistent blend accuracy (±0.5% concentration)

Homogeneous mixture in single pass

✓ Multi-Beverage Compatibility

Carbonated drinks (sodas, sparkling water)

Non-carbonated applications:

• Juice/paste beverages

• Fermented drinks (kombucha, kvass)

• All major soft drink categories

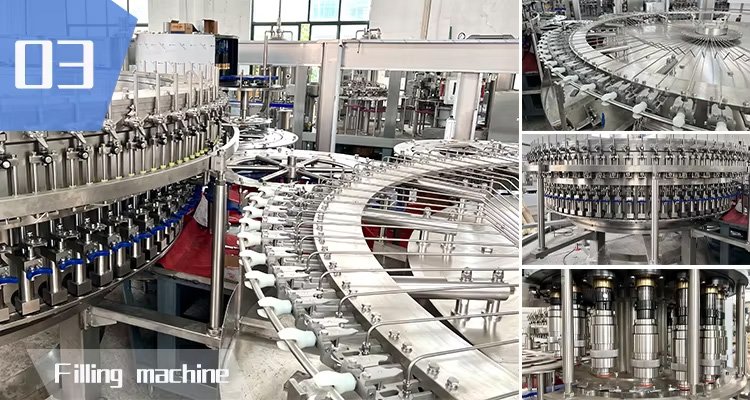

Filling Machine

Premium Filling Valve Technology

Clean, safety-certified valve bodies

Guaranteed material quality

Advanced Isobaric liquid filling bottling machine

±0.5% volume accuracy

30% less CO₂ consumption vs standard valves

Patented Water-Saving Rinsing

100% bottle coverage guarantee

Zero unrinsed bottles at stations

40% water reduction

Labeling Machine

- According to customer request and market demand ,we provide the better solution for the final product packagedesign,We have various kinds of options .like PVC sleeve label ,BOPP hot glue label,Adhesive stick label,Cold glue paper label .

Bottle Packing System

- We supply the different bottle package deisgn , Film package ,Carton box wrapper ,Film with tray package and so on .

Bottle Blowing System

- We supply the Complete Bottle Blowing System ,start from PET preform injection molding machine ,and Bottle blowing

machine,including air compressor system and water cooling system .

Why Choose Us

-

Direct Manufacturer: With over 10 years of experience in developing and manufacturing beverage and liquid food filling machines. Our plant spans 4000m², and we have independent property rights.

-

Professional Export Team: We offer stable product quality, fast delivery, and clear communication, ensuring smooth international transactions.

-

Custom Manufacturing: Our skilled technical team can design machines in various sizes and configurations to meet your unique specifications.

-

Strict Quality Control: We never ship equipment without customer approval. Every machine undergoes 24-hour testing before shipping, and we ensure quality is controlled at every production stage.

-

12-Month Warranty: All our equipment comes with a 12-month warranty, and we provide lifetime technical support for all products.

-

Fast Spare Parts Availability: We supply spare parts quickly and at cost price, minimizing downtime and ensuring operational continuity.