Description

GCGF32-32-10 Water Filler Machine with High-Speed Valve

Product Description

GCGF32-32-10(High-Speed Valve) |

|||

| Capacity (BPH) | Power supply | Overall dimension | Weight (KG) |

| 18000-20000/bph | 3.92 KW | 3550×2650×2700 | 5500 |

Rinsing System (32 Heads)

The 32-head rinsing system performs high-speed bottle washing and ensures thorough internal and external cleaning before filling. Each of the 32 rinsing nozzles aligns precisely with the bottle mouth and sprays high-pressure water or disinfectant to achieve effective sterilization. The system grips and inverts bottles in a synchronized manner to ensure consistent cleaning without causing any damage.Made of high-quality stainless steel, it offers strong corrosion resistance, easy maintenance, and long service life—ideal for water, beverage, and food bottling lines requiring hygienic and efficient preparation.

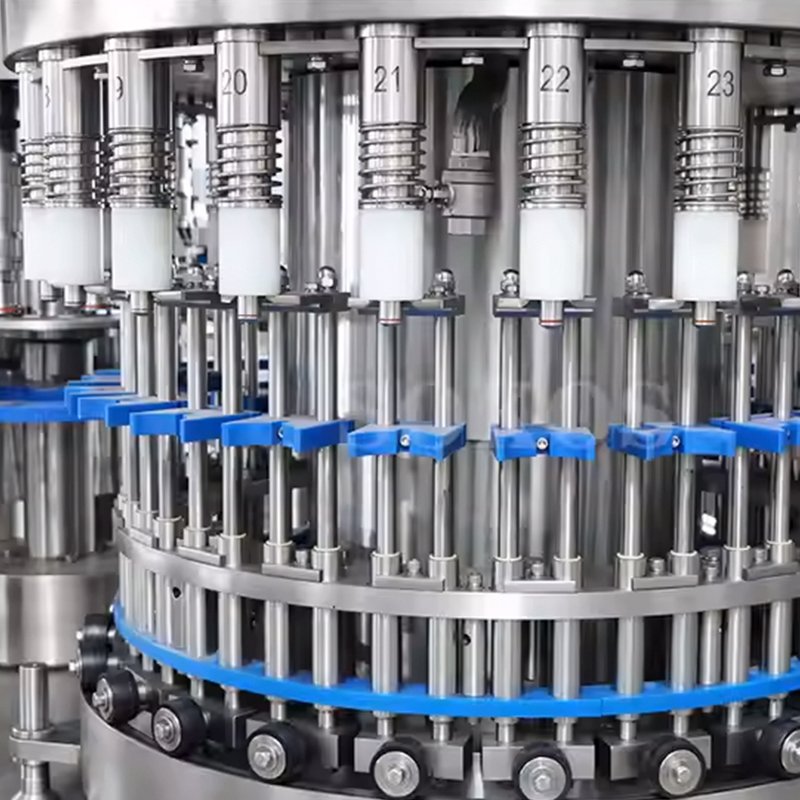

Filling System (32 Heads)

The 32-head filling system is engineered for high-efficiency liquid bottling, delivering fast, accurate, and hygienic performance. Equipped with 32 precision filling valves, the system ensures uniform liquid levels and minimal product loss. It supports gravity or pressure filling depending on the product type, making it suitable for water, juice, and other non-carbonated beverages. The contact parts are made of food-grade stainless steel to ensure safety and corrosion resistance. With smooth operation and easy adjustment, this system is ideal for medium to large-scale production lines seeking reliable and consistent filling results.

Capping System (10 Heads)

The 10-head capping system ensures fast, accurate, and reliable sealing for various bottle types. Each capping head precisely applies torque-controlled force to securely tighten caps without damaging bottles or caps. The system handles different cap sizes and materials, making it suitable for water, juice, and other liquid products. With synchronized bottle positioning and cap application, it maintains high-speed operation and consistent performance. Constructed from durable, food-grade stainless steel, the system offers excellent corrosion resistance, easy maintenance, and long-term stability—ideal for modern automated bottling lines.

Why Choose Us

-

Direct Manufacturer: With over 10 years of experience in developing and manufacturing beverage and liquid food filling machines. Our plant spans 4000m², and we have independent property rights.

-

Professional Export Team: We offer stable product quality, fast delivery, and clear communication, ensuring smooth international transactions.

-

Custom Manufacturing: Our skilled technical team can design machines in various sizes and configurations to meet your unique specifications.

-

Strict Quality Control: We never ship equipment without customer approval.we test every machine for 24 hours before shipping, and furthermore, we control quality at every stage of production.

-

12-Month Warranty: All our equipment comes with a 12-month warranty, and we provide lifetime technical support for all products.

-

Fast Spare Parts Availability: We supply spare parts quickly and at cost price, minimizing downtime and ensuring operational continuity.