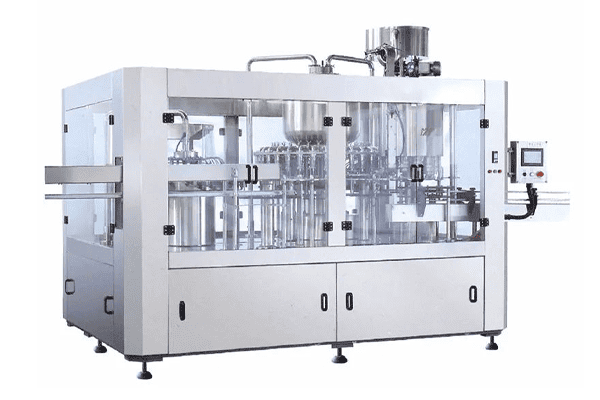

Fully-Automated Water Bottle Manufacturing Machine

Compact 3-in-1 System for Rinsing, Filling & Capping

Efficient, flexible, and engineered for both water and juice bottling under atmospheric or low-vacuum conditions.

Versatile Filling Applications

This machine integrates rinsing, filling, and capping into one compact unit, making it ideal for filling mineral water, purified water, and juices into PET or plastic bottles.

With a temperature control unit, it also supports hot filling. Quick bottle type changes are enabled by easy-to-use handwheels.

Automated by a PLC system, the machine ensures stable operation, with photoelectric sensors monitoring performance. The VFD-controlled infeed conveyor syncs with the main drive for smooth bottle flow.

Low-Vacuum Filling for Glass Bottles

Perfect for glass containers used in alcoholic beverages and juices, this machine supports low-vacuum filling and works with ROPP and plastic screw caps—ideal for premium products.

Key Features & Advantages

Streamlined Bottle Feeding

-

Direct air conveyor links to the star wheel, removing the need for feed screws and chains.

-

Simplifies bottle changes.

Universal Bottle Handling

-

Gripper transport system eliminates height adjustment.

-

Only minimal component changes (e.g., guide plates, star wheels) are required.

Efficient Rinsing

-

Durable, high-performance rinsing heads ensure optimal bottle cleanliness.

High-Speed Gravity Filling

-

Fast and precise large-flow gravity valves with ±0.5% accuracy.

-

No dripping, reduced product waste.

Smooth Bottle Discharge

-

Height changes handled via spiral lower plate, no discharge conveyor adjustments needed.

Smart Automation

-

Industrial-grade PLC manages fault detection, speed control, and recipe settings.

-

VFDs on motors optimize energy use and speed.

Supported Applications & Containers

-

Containers: PET, Plastic, and Glass Bottles

-

Products: Water, Juice, Soft Drinks, Alcoholic Beverages

-

Cap Types: Screw (Plastic), ROPP (Aluminum)

| Model | DCFG16-12-8 | DCFG18-18-6 | DCFG24-24-8 | DCFG32-32-10 | DCFG40-40-10 | DCFG60-60-15 |

| Production(500ml/bph) | 4000 | 7000 | 10000 | 14000 | 18000 | 24000 |

| Number of rinsing heads | 16 | 18 | 24 | 32 | 40 | 60 |

| Number of filling heads | 12 | 18 | 24 | 32 | 40 | 60 |

| Number of capping heads | 8 | 6 | 8 | 10 | 10 | 15 |

| Trial bottle type | Round bottle/square bottle | |||||

| Neck size(mm) | Φ50-Φ90 | |||||

| Bottle height(mm) | 150-310 | |||||

| Compressed air pressure(Mpa) | 0.5-0.7 | |||||

| Rinsing medium | Sterile water | |||||

| Rinsing water pressure(Mpa) | 0.25 | |||||

| Total power(kwv) | 3.13 | 3.84 | 4.1 | 5.6 | 7.5 | 10.8 |

| Dimensions(mm) | 2250*1640*2100 | 2340*1800*2100 | 3050*2060*2100 | 4050*2300*2100 | 4720*3550*2100 | 4800*3600*2100 |

| Weight(kg) | 2500 | 3000 | 4000 | 5000 | 7600 | 8500 |

Why Choose This Filling Machine?

Sokos delivers a space-saving, high-efficiency solution that boosts line flexibility and precision. From easy bottle changes to advanced automation, this system meets the evolving needs of modern beverage producers.