Alibaba-Sourced Turnkey Solution Earns Client Referrals & 99% Uptime

Client Background

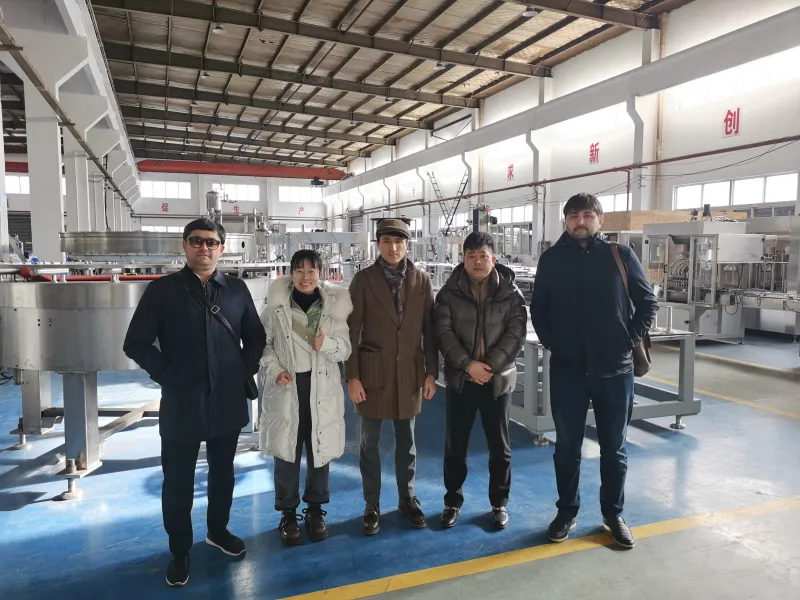

An Uzbek entrepreneur identified a promising gap in the beverage market. With limited prior experience in manufacturing but strong local distribution connections, he turned to Alibaba to source reliable 5-gallon barrel fillers that could support his ambitious startup goals.

His key requirement was a production capacity of 300 barrels per hour, enough to supply both direct-to-consumer services and local retailers. After extensive supplier comparisons and video inspections, He decisively chose the Sokos factory.

Just three months after launch, the line was running at over 90% uptime. Customer feedback was positive—especially regarding barrel sealing quality and hygiene standards. Today, his brand is supplying over 20 neighborhoods in Tashkent, and discussions are underway to expand into Horezm and Samarkand.

Technical Selection Process

Sales Manager Vicky led detailed virtual consultations. Consequently, the client visited SOKOS for factory dry-run testing. They prioritized sanitary design and minimal CIP downtime.

Precision Line Specifications

| Component | Technical Specification |

|---|---|

| Filling Method | Rotary Gravity Filler with Cam-Driven Valves |

| Rinsing System | 4-Station Rotary Jet Rinsers (304L SS) |

| Sealing | Automatic Spindle Capping (Torque Control) |

| Conveyance | Low-Friction Roller Chains (Food-Grade Lubricant) |

| Control System | Siemens PLC with HMI + Production Data Logging |

Performance Validation

The drum filling equipment achieved 318 BPH consistently. Changeover time reduced to 8 minutes between flavors. Critical metrics:

-

99.1% filling accuracy (±10ml)

-

<0.2% cap rejection rate

-

2.7% utility savings vs competitors

Business Impact & Referrals

The client reached full ROI within just 14 months. Highly satisfied with the performance of our 5-gallon barrel fillers, which are fully compatible with autoclave processes, he went on to refer three regional partners. He even shared production floor footage demonstrating their flawless, zero-leak operation—further validating the equipment’s reliability and efficiency.

For more information please contact manager Vicky

WhatsApp:+86 17351259218

Email: benny.wang1@sokosmachinery.com