Precision Plunger Filling: 8,000 BPH for Chef Food Industries

Chef Food Industries (Kanaipur, Faridpur, Bangladesh) partnered with us. Their goal? Automate Nata de Coco bottling. Under Mohammad Safiqul Islam’s leadership, we delivered. Our complete solution featured the GF14-8 plunger filling machine. It achieves 8,000 bottles/hour.

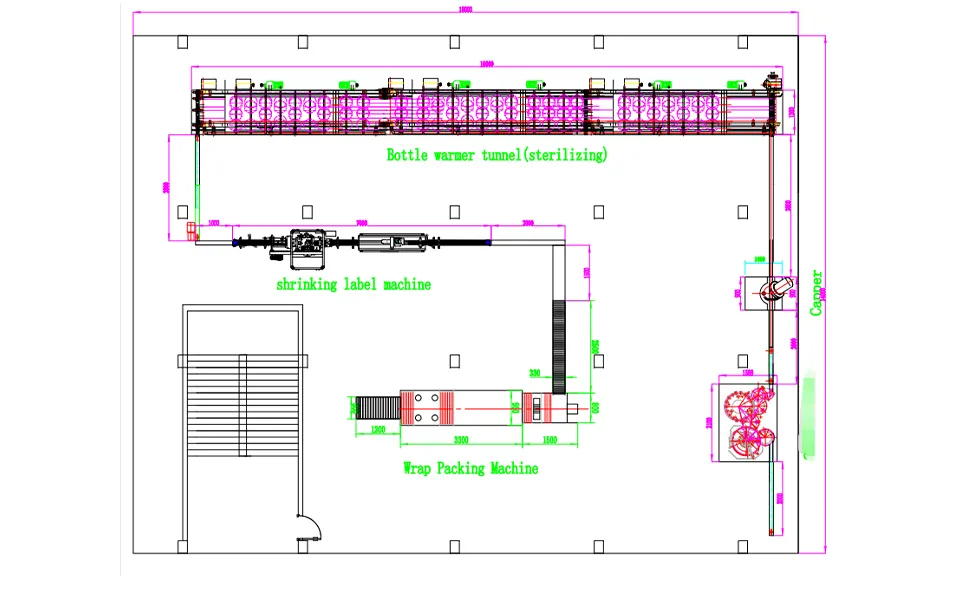

Custom Bottle & Layout Design

First, we designed special PET bottles with optimized necks and shapes to ensure smooth interaction with the plunger valve. Then, we laid out the factory efficiently, integrating the 8000 BPH filling machine with detailed engineering drawings. We also added an unscrambler to streamline operations. Finally, we carefully planned material flow paths to eliminate bottlenecks completely.

High-Performance Plunger Filling Machine System

The core was our GF14-8 plunger filler. Key features include:

✅ 16 stainless steel pistons.

✅ Particulate-friendly valves (ideal for coconut gel).

✅ Auto volume adjustment (±0.5% accuracy).

Additionally, an automatic bottle unscrambler was paired. This ensured continuous feeding.

Proven Operational Results

Now, the plunger filler delivers consistently:

✔️ Steady 8,000 BPH throughput.

✔️ Zero gel particle damage.

✔️ 30% less waste versus before.

Mr. Islam confirmed its success: “This plunger system handles our delicate Nata de Coco perfectly. It also hits target speeds.”

If you want to know the situation of this customer or have any needs, please contact us