I. Digital bond for cross-border cooperation

“When Suzhou’s smart equipment meets Ethiopia’s mango pulp, the Chinese solution is reshaping the boundaries of the African juice industry.” In 2023, when Bulgarian entrepreneur Ivan discovered SOKOS through Alibaba International Station, the Chinese beverage machinery manufacturer had deployed more than 200 smart production lines around the world.

Three steps of cooperation:

Cloud dialogue (Day 1-15): Through 12 cross-border video conferences, the SOKOS technical team accurately analyzed customer needs – designed a 40-40-10 station structure (40 rinsing, 40 filling, 10 capping) for Ethiopian high-fiber mango raw materials (pulp content ≥ 32%)

Implementation of the plan (Day 16-60): Customized development includes a special rinsing system for tropical fruits (water temperature gradient control ±1℃), a drip-proof filling valve group (vacuum degree -0.08MPa), and a torque self-test capping head (accuracy ±0.15N·m)

Installation and commissioning (Day 61-78): The Chinese engineering team stayed on site for 18 days to complete the equipment joint commissioning and simultaneously trained 23 local technicians

Sokos juice production line, which has obtained CE and ISO 9001 certification, finally achieved 98% equipment overall efficiency (OEE), an increase of 21 percentage points over the average level of the African market.

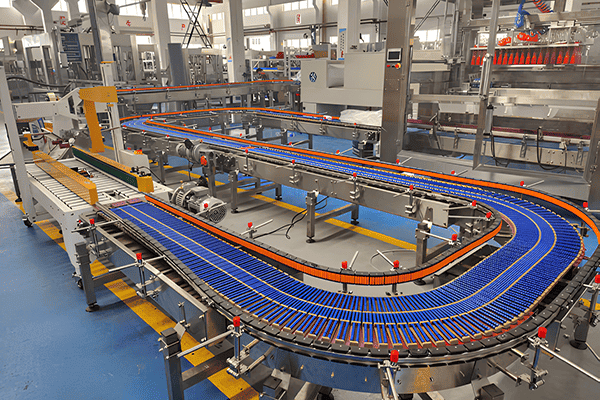

2. Technical secrets of the 40-40-10 revealed by sokos juice production line

2.1 Revolutionary upgrade of the rinsing system

In view of the characteristics of African water quality (conductivity 800-1200μS/cm), SOKOS innovatively designed:

Four-stage countercurrent flushing module (water consumption reduced to 0.12m³/10,000 bottles)

Self-cleaning nozzle array (aperture 0.3mm, pressure 0.35MPa adjustable)

Bottle mouth visual inspection system (foreign body recognition accuracy 0.1mm²)

“The residual water rate of traditional rinsers is usually 3-5 drops, and our double air knife drying system can control this to ≤1 drop.” The test data presented by Li Tao, a mechanical engineer of the project, showed that the qualified rate of rinsing reached 99.89%.

2.2 Millimeter-level control of filling accuracy

In a high temperature and high humidity environment (32℃/75%RH), the equipment achieves:

Dynamic weighing compensation (filling error ±0.8ml)

Nitrogen replacement system (headspace oxygen content ≤0.6%)

Instantaneous flow PID control (fluctuation rate <1.2%)

“This servo-driven filling system can complete bottle mouth positioning within 0.2 seconds.” Field operator Addis pointed to the jumping data on the HMI screen, “Even if the preform is tilted at 15°, it can still be accurately filled.”

2.3 Intelligent evolution of capping technology

Facing the recycled PET bottle caps unique to the African market (recycled materials account for 30-40%), SOKOS has created the following:

Three-dimensional force feedback capping head (triple monitoring of pressure/torque/angle)

Cap type self-learning system (compatible with 12 international standard bottle caps)

Online sealing test (negative pressure test -80kPa for 10 seconds)

The qualified rate of capping has increased from 93.5% of traditional equipment to 99.2%, and the equipment changeover time has been shortened to 7 minutes.

3. Panoramic view of 178-day production empirical data

As of project acceptance, the production line has achieved:

Daily average capacity: 208,000 bottles (500ml)

Bottle loss rate: 0.07% (industry average 0.5-0.8%)

Unit energy consumption: 0.085kW·h/box (18% lower than German equipment)

| Core parameter comparison table: | ||

| Indicators | European equipment | SOKOS equipment |

| Stability of rinsing water temperature | ±3℃ | ±0.8℃ |

| Filling speed | 24,000BPH | 30,000BPH |

| Capping qualification rate | 93.50% | 99.20% |

| Comprehensive energy consumption | 0.103kW·h/box | 0.085kW·h/box |

“What surprised me most was their response speed,” I said during the acceptance ceremony. “When we discovered mango fiber was blocking the bottle rinsing nozzle, the Chinese engineers shipped us a special filter assembly within just 48 hours.”

IV. Adaptive innovation made in China for Africa

4.1 Power fluctuation solution

For the voltage fluctuation of the Ethiopian power grid (±15%), the equipment has built-in:

Wide voltage servo drive system (310-460V adaptive)

Supercapacitor instantaneous compensation module (200ms power interruption endurance)

Intelligent sleep function (standby energy consumption <0.8kW)

4.2 Localized operation and maintenance system

Augmented reality remote guidance system (5G smart glasses assist maintenance)

Spare parts pre-positioning algorithm (ship key components by sea in advance based on operation data)

Multilingual operation interface (supports switching between Amharic/English/Chinese)

V. From equipment delivery to value symbiosis

In 178 days of operation, SOKOS has created deep value far beyond equipment trading:

Technology spillover: Cultivate the first local team in Africa to master the operation and maintenance of intelligent production lines

Standard upgrade: Promote the Ethiopian juice industry to improve the filling accuracy standard from ±3ml to ±1ml

Capacity leap: Help the factory obtain EU BRC certification, and increase exports by 340%

“This is not a simple equipment purchase, but a transplant of industrial capabilities.” Ivan pointed to the real-time data on the workshop electronic board, “Now my German customers are beginning to believe that juice made in Africa can also meet DIN standards.”

Ⅵ.Chinese precision on the trust chain

From the R&D center in the Jiangnan water town to the production workshop on the East African plateau, this 40-40-10 production line has been running stably for 178 days and 4,200 hours, interpreting the hard-core strength of Chinese manufacturing. When the last PET bottle completed the capping at a beat of 0.28 seconds, the efficiency number on the screen was not only a technical parameter, but also a trust scale spanning 8,000 kilometers.

In the beverage machinery arena, the real kings will always belong to those companies that can look up to the stars for innovative breakthroughs and bend down to meet customer needs — just like the Sokos juice production line, which embodies the spirit of both technological excellence and practical customization. This may be the deep code for China’s smart manufacturing to win the world’s applause.