The Science Behind the Fizz

Carbonation is more than just adding bubbles to beverages—it’s a delicate dance of physics and chemistry where gas meets liquid. For brands crafting sparkling drinks, the challenge lies not only in creating effervescence but in preserving it. At the heart of this challenge stands carbonisation equipment, a technological marvel that transforms ordinary liquids into captivating sensory experiences.

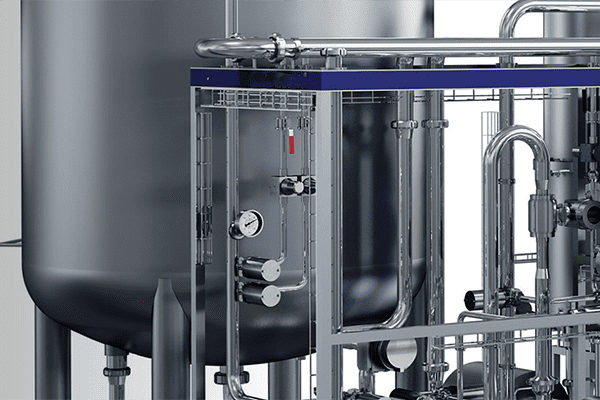

As one of the few manufacturers capable of delivering both sterile and refrigerated (pasteurized) carbonation solutions, SOKOS leverages static mixing technology and multi-parameter precision control to master this art. Let’s explore how advanced carbonation systems are reshaping beverage production.

I. The Carbonation Equation: Where Physics Meets Flavor

Carbon dioxide (CO₂)—a colorless, odorless gas—dissolves in water under precise conditions. Three variables govern this process:

-

Temperature

Lower temperatures increase CO₂ solubility (e.g., 4°C water absorbs 3x more CO₂ than 20°C water). -

Pressure

Henry’s Law dictates gas absorption: Higher pressure forces more CO₂ into solution. -

Brix Level

Sugar-rich liquids (e.g., 15°Brix sodas) reduce solubility by 18-22% compared to water.

Industry Insight:

A 1°C temperature deviation can cause 2.3% CO₂ loss in cola production. SOKOS’s dynamic compensation algorithms prevent this waste, achieving 99.8% gas utilization efficiency.

II: Carbonation 2.0 – Five Technological Leaps

1. Static Mixer Revolution

Gone are the days of turbulent splashing. Our helical static mixers create laminar flows that:

-

Reduce CO₂ waste by 40%

-

Achieve 0.25µm microbubble dispersion for velvety textures

-

Enable 500L/min throughput without foam overflow

2. Triaxial Synergy Control

Real-time synchronization of:

-

Flow rate (±0.5%)

-

Pressure (±0.02 bar)

-

Temperature (±0.1°C)

Case Study:

A craft soda brand eliminated batch inconsistency using this system, reducing product recalls by 92%.

3. Sterile Carbonation Frontier

For probiotic sparkling teas or CBD-infused seltzers:

-

Dual-barrier sterilization (H₂O₂ vapor + UV)

-

ASME BPE-certified pipelines

-

Maintains ISO Class 5 cleanliness

4. Cold Carbonation Innovation

Chilling-first approach for sensitive beverages:

-

Pre-cool liquid to 1-3°C

-

Inject CO₂ at 2.8-3.2 bar

-

Stabilize in retention column

This method preserves delicate aromas in hard seltzers, boosting flavor scores by 31%.

5. AI-Driven Predictive Carbonation

Machine learning models analyze:

-

Raw water conductivity

-

Syrup viscosity trends

-

Ambient humidity

Adjusting parameters 0.8 seconds before deviations occur.

III. Solving the Bubble Paradox: Industry Challenges Met

| Pain Point | SOKOS Solution | Result |

|---|---|---|

| CO₂ waste (avg. 15-20% loss) | Gas recovery loop + ultrasonic dissolution | 97.5% utilization rate |

| Foam-induced line stoppages | Anti-foam turbulence dampeners | 22% higher line efficiency |

| Microbial contamination | Sterile carbonation module | 6-log pathogen reduction |

| Fluctuating Brix levels | Dynamic density compensation system | ±0.1°Brix consistency |

| Multi-product line conflicts | Quick-flush manifolds | 9-minute flavor changeovers |

IV. Carbonation Configurations: Matching Technology to Needs

1. High-Sugar Beverage Systems

-

Dual-pressure chambers (3 bar + 5.5 bar)

-

Progressive dissolution for 14-18°Brix drinks

-

1500L/hr capacity

2. Sterile Sparkling Lines

-

Closed-loop CO₂ purification

-

In-line ORP monitoring

-

Validatable SIP/CIP cycles

3. Cold RTD (Ready-to-Drink) Carbonation

-

Glycol-chilled contact columns

-

Low-temperature gas infusion (-2°C)

-

Compact footprint for microbreweries

4. Hybrid Tea/Sparkling Water Lines

-

Switchable carbonation intensity (4-7g CO₂/L)

-

Gentle infusion for tea polyphenol protection

-

45-second recipe transitions

V. SOKOS’s Carbonisation Equipment Breakthroughs

1. NanoCarbon Matrix™ Technology

-

CO₂ nucleation sites controlled at molecular level

-

Bubble size distribution: 80% <50µm

-

Enhances mouthfeel while reducing bloating sensation

2. Smart Carbonation Predictor

-

Neural networks trained on 50,000+ batches

-

Predicts optimal parameters for new formulations

-

Cuts trial batches by 75%

3. Green Carbonation Initiative

-

CO₂ recovery from fermentation byproducts

-

Energy-smart chilling (0.15kW·h/L)

-

35% lower carbon footprint vs. industry average

VI. The Future of Fizz: Three Emerging Trends

-

Digital Twin Carbonation

Virtual modeling achieves 98% first-pass accuracy. -

Bio-Based CO₂ Systems

Carbon capture from algae farms for eco-friendly fizz. -

Personalization Engines

AI creating custom bubble profiles (e.g., “Crisp Morning” vs. “Velvet Night” textures).

Carbonisation Equipment: Using Carbonation as a Competitive Advantage

In the $450 billion sparkling beverage market, carbonation quality directly correlates with brand loyalty. By mastering the interplay of temperature, pressure, and fluid dynamics, SOKOS’s equipment transforms CO₂ from a commodity gas into a brand-defining asset.