Classification and Applications of Filling Machines

Filling machines are packaging equipment designed to dispense precise quantities of products into various containers. They can be classified based on two main criteria:

-

Material Type:

-

Liquid Filling Machines

-

Paste Filling Machines

-

Powder Filling Machines

-

Granule Filling Machines

-

-

Automation Level:

-

Semi-Automatic Filling Machines

-

Fully-Automatic Filling Machines / Production Lines

-

Granule Filling Equipment

-

Working Principle: Based on advanced filling technology with improved design, granule fillers feature simple structure, high precision, and user-friendly operation. They utilize an anti-dripping lifting filling head mechanism. Filling valves are pneumatically controlled for enhanced accuracy. Both filling volume and speed are adjustable.

-

Applications: Ideal for small bag packaging in pharmaceuticals, food, chemicals, and pesticides. Suitable for granular products such as: pharmaceutical granules, sugar, coffee, instant drinks, tea, MSG, salt, seeds, desiccant, and other fine granular materials.

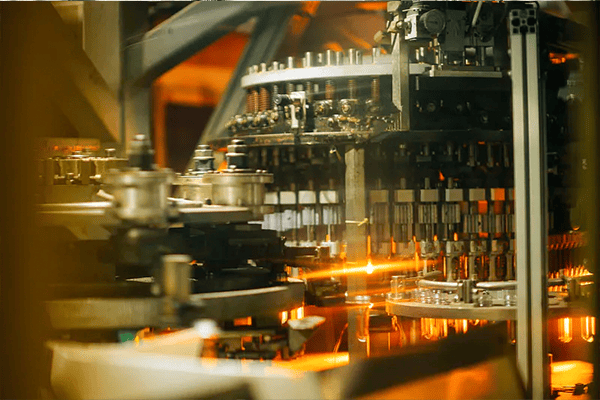

Liquid Filling Machines

Liquid filling machines are further categorized by their filling pressure principle:

-

Atmospheric Pressure Fillers: Rely on liquid gravity for free-flow filling. Performance depends on liquid viscosity and gas content. Filling modes include timed filling and volumetric filling.

-

Vacuum Fillers: Operate when the bottle pressure is lower than atmospheric pressure. Simple structure, high efficiency, typically used for highly viscous liquids.

-

Pressure Fillers: Operate above atmospheric pressure. Two subtypes:

-

Iso-pressure Filling: Liquid flows by gravity when pressure in the storage tank equals the bottle pressure.

-

High-pressure Filling: Liquid flows due to pressure differential (tank pressure > bottle pressure). Commonly used in high-speed automatic filling machines production lines.

-

-

Applications: Widely used for filling liquids such as: lotions, care solutions, oral liquids, disinfectants, eye washes, nutritional liquids, beverages/alcohol, injections, pesticides, pharmaceuticals, perfumes, edible oils, lubricants, and liquids for specialized industries.

Gas Filling Machines

-

Working Principle: Relatively simple operation, using a booster pump to fill gases under pressure, similar to pressure liquid fillers. Critical operating requirements include well-ventilated areas, low temperatures, and flame-free environments.

-

Applications: Extensively used for filling various gas products, including: pure oxygen, compressed air, cartridge gases (e.g., for whipped cream dispensers, CO₂ cartridges), natural gas, coal gas, nitrogen, carbon dioxide, etc. Modern gas filling machines automatic systems enhance safety and efficiency in these processes.