Essential Maintenance Guide for Reagent Filling Machines

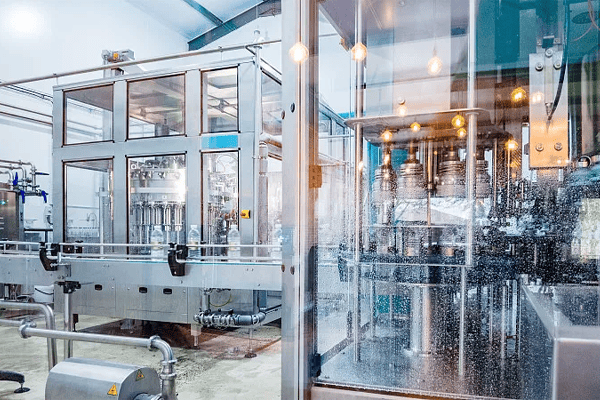

Reagent filling machines are precision automated systems designed for accurate liquid dosing and packaging, widely used in pharmaceuticals, food & beverage, cosmetics, chemicals, and laboratory environments. Ideal for small-batch or multi-product operations, they can handle a wide range of materials—from eye drops and injectables to edible oils, shampoos, and pesticides. Regular filling machine maintenance is essential to ensure consistent performance, prevent downtime, and extend equipment lifespan in these demanding applications.

Follow this comprehensive 7-step maintenance protocol to ensure accuracy, extend equipment life, and prevent costly downtime:

1. Deep Cleaning Procedures

-

Post-Use Protocol: Immediately clean all liquid-contact parts: nozzles, pipelines, valves, and dosing mechanisms. Prevents residue buildup and cross-contamination.

-

Viscous/Corrosive Solutions: Use CIP systems or pH-neutral detergents for internal channel flushing.

-

Component Care: Regularly wipe sensors, cylinders, and pneumatic parts to maintain responsiveness.

2. Precision Lubrication

-

Moving Parts: Lubricate chains, sprockets, gears, and conveyor tracks monthly.

-

Critical Components: Apply high-grade lithium grease or anti-corrosion lubricant to ball screws, guide rails, and sliders. Remove old grease/debris during reapplication.

3. Electrical & Pneumatic Checks

-

Control Systems: Inspect PLCs/HMIs for loose wiring, damaged plugs, or error codes.

-

Sensor Calibration: Test and recalibrate sensors via HMI; replace if unresponsive.

-

Air System Integrity: Confirm zero leaks. Maintain pressure at 0.5–0.7 MPa (check manufacturer specs).

4. Dosing System Calibration

-

Volume Verification: Use certified graduated cylinders or precision scales. Target ±1% accuracy.

-

Flow Meter Tuning: Adjust PLC pulse signals/timing for precise volumetric control.

-

Component Wear: Monitor sensors, load cells, and metering parts—replace if performance drifts.

5. Corrosion Prevention & Environment

-

Workspace Requirements: Operate in dry, ventilated spaces. Eliminate acid/alkali fumes.

-

Aggressive Chemicals: Specify corrosion-resistant pumps/seals (PTFE, PVDF) when filling reactive substances.

6. Safety & Failure Prevention

-

Operator Training: Ensure staff master E-stop functions, alarm codes, and manual/auto modes.

-

Hazard Zones: Never contact filling heads, actuators, or moving parts during operation. Keep liquids away from control cabinets.

-

Safety Checks: Weekly test emergency stops, door interlocks, and alarms.

7. Maintenance Tracking & Lifecycle Optimization

-

Digital Logs: Record dates, tasks, technicians, and resolutions for every service.

-

Predictive Maintenance: Use MES/CMMS software to track part lifespans and schedule replacements.

-

Smart Upgrades: Integrate IoT-enabled machines with cloud platforms for remote diagnostics, reducing downtime by 30-50%.

Effective filling machine maintenance is critical for ensuring long-term accuracy, safety, and reliability in reagent packaging operations. By following a structured 7-step protocol—from deep cleaning and lubrication to sensor calibration and predictive tracking—you can reduce downtime, extend equipment life, and maintain optimal dosing precision across diverse production environments.

For technical questions, please contact us:https://sokosfillingmachine.com/contact-us/