Volumetric Accuracy Meets Versatility

Core Working Principle: 3-Step Cycle

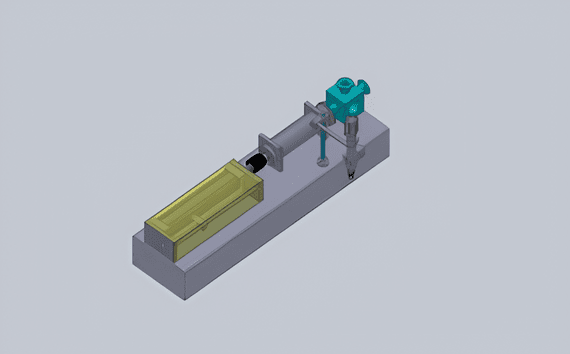

Unlike complex filling systems, piston filling machine operate on a straightforward volumetric principle:

-

Intake Stroke: Valve connects hopper to cylinder → Piston retracts, drawing product into the cylinder chamber.

-

Valve Rotation: Valve switches path from hopper to nozzle.

-

Discharge Stroke: Piston pushes downward → Product flows through nozzle into containers.

Why volume stays consistent:

The fixed interior volume of the cylinder ensures ±0.5% fill accuracy – critical for high-value products like cosmetics or pharmaceuticals.

Where Piston Fillers Excel: Handling Challenging Products

Ideal for materials that defeat other fillers:

-

High-Viscosity Fluids: Pastes, creams, peanut butter

-

Semi-Solids & Particulates: Salsas (with vegetable chunks), cottage cheese, adhesives

-

Temperature-Sensitive Products: Customizable with heated hoppers to improve flow

Real-World Application: A food manufacturer filling chunky mango salsa uses a rotary valve piston filling machine to prevent particle damage while maintaining portion control.

5 Key Advantages Driving Industrial Adoption

-

Unmatched Versatility

From water-thin chemicals to 50,000cps cosmetic creams – one piston filling machine adapts via interchangeable nozzles and cylinder sizes. -

Particulate-Friendly Design

Rotary valve models handle solids up to 12mm (e.g., olives in tapenades) without clogging. -

Rapid Changeovers

Adjust fill volumes in minutes via handwheel-controlled piston stroke length. -

Sanitary Compliance

Full FDA/USDA-grade material options (316L stainless steel, EPDM seals). -

Scalable Automation

Benchtop units to 20-nozzle rotary lines with 50+ containers/minute throughput.

Customization Options for Specific Needs

Tailor your machine to the product – not vice versa

| Component | Customization Impact |

|---|---|

| Cylinder/Piston | Volume range from 5ml to 5L+ |

| Nozzles | Wide-bore for chunks, narrow for vials, anti-drip for solvents |

| Hopper System | Direct-draw from drums, heated tanks for waxes, nitrogen blanketing |

| Valve Type | Rotary (particulates) vs Check Valve (free-flowing liquids) |

Pro Tip: For products like honey changing viscosity with temperature, our engineers integrate jacketed hoppers with PID temperature control.

Why Leading Brands Choose Piston Technology

When filling consistency impacts profitability – salad dressing brands, cosmetic labs, and chemical packagers rely on piston filling machines for:

-

Zero waste: Precise volumetric control cuts product giveaway

-

Minimal downtime: Self-priming models draw directly from drums

-

Future-proofing: Modular designs allow upgrades to automation

Ready to optimize your filling line?