Volumetric Fully Automatic Liquid Filler: Engineering Precision for Industrial Packaging

Volumetric liquid filler features advanced design for viscous liquids and hazardous materials.

Core Advantages Driving Adoption

-

Dual-Head Speed Architecture

-

Simultaneous piston filling doubles throughput (40 containers/min)

-

Bottom-up filling motion prevents splashing (±0.5% accuracy)

-

-

Future-Proof Modularity

-

Quick-change tooling adapts to container sizes in <15min

-

ISO-compliant interfaces for third-party integration

-

-

Explosion-Proof Safety

-

Full pneumatic control (ATEX Zone 2 certified)

-

Vapor-recovery filling nozzles reduce solvent emissions by 90%

-

Precision Engineering Breakdown

Material Science Foundation

| Component | Material Specification | Industry Standard |

|---|---|---|

| Product Contact | SUS304 Stainless | FDA 21 CFR 211.65 |

| Conveyor Chains | Engineering Plastic | ISO 186:2018 |

| Structural Frame | Aerospace-grade Aluminum | EN 754-2 |

Patented Container Handling

Automated Bucket Separation System:

-

Stack Loading: 9-layer bucket stacks (90 units)

-

Robotic Extraction: Vacuum gripper isolates single units

-

Orientation: 90° rotation for filling position

Eliminates manual handling injuries in chemical plants

Filling Subsystem: How Volumetric Accuracy is Achieved

Four Critical Components:

-

Hopper: 100L capacity with CIP cleaning

-

Piston Metering Pumps: ±0.2% volumetric repeatability

-

Anti-Drip Nozzles: Teflon-coated with retraction system

-

Z-Axis Actuator: Programmable filling height adjustment

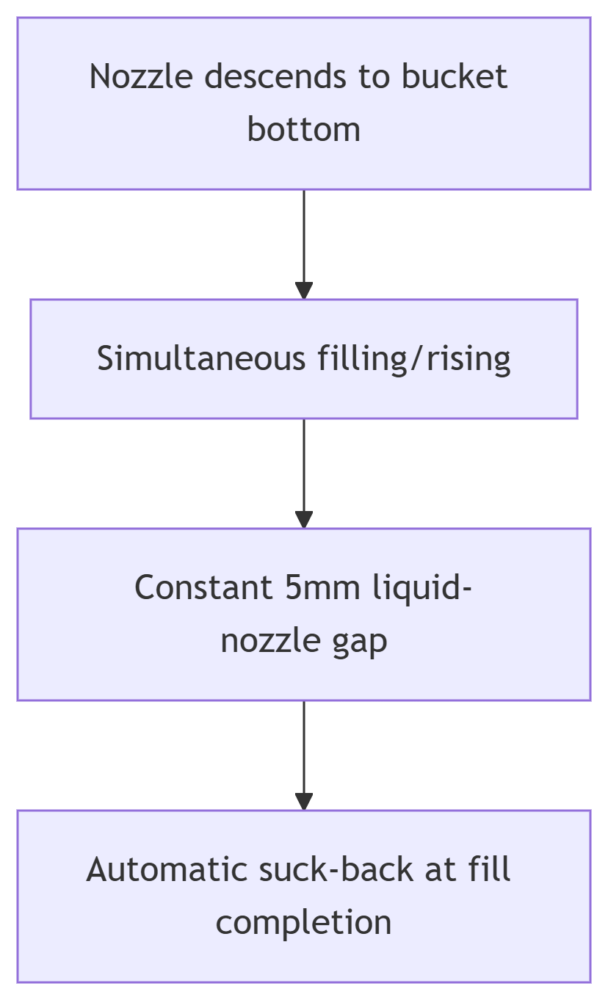

Operation Sequence:

Intelligent Capping & Sealing

Three-Stage Closure Process

-

Cap Separation:

-

Vibratory bowl feeder aligns caps

-

Vacuum gripper picks individual caps

-

-

Precision Placement:

-

Laser-guided positioning (0.1mm tolerance)

-

Anti-static systems for flammable vapors

-

-

Force-Controlled Sealing:

-

Programmable pressure profiles (50-200 PSI)

-

Real-time torque monitoring

-

Technical Specifications: Beyond Standard Models

| Parameter | Performance | Advantage |

|---|---|---|

| Speed | 40 buckets/min | 3× manual operation |

| Viscosity Range | 1-50,000 cP | Handles oils to pastes |

| Container Size | 5-50L buckets | No mechanical changeover |

| Accuracy | ±0.5% of setpoint | Saves $18k/year in material giveaway |

Workflow Synchronization

Automated Production Sequence:

-

Bucket Loading: Robotic destacker → Conveyor indexing

-

Filling Phase: Bottom-up volumetric filling (10-60 sec/unit)

-

Sealing Station: Automatic cap placement + compression

-

Traceability: Laser coding + Label application

-

Output: Pallet-ready packaged goods

Control System Features:

-

OPC-UA communication protocol

-

Recipe storage for 200+ products

-

Predictive maintenance alerts

Why Leading Manufacturers Choose This Volumetric Filler

Critical Differentiators:

-

Zero Cross-Contamination:

-

Full CIP capability with 3D spray balls

-

Material changeover in <20 minutes

-

-

Hazardous Material Compliance:

-

Nitrogen purging option

-

Intrinsically safe components

-

-

Energy Efficiency:

-

Regenerative braking on servo motors

-

40% lower air consumption vs competitors

-

Industry Applications:

-

Chemicals: Solvents, adhesives, lubricants

-

Food: Cooking oils, syrups, dressings

-

Cosmetics: Lotions, creams, shampoos

Custom Engineering Options

Tailored solutions for complex requirements

Specialized Upgrades:

-

Explosion-proof rating (ATEX/IECEx)

-

High-viscosity packages (200,000 cP)

-

FDA-compliant documentation packages

-

Remote monitoring via IIoT gateway