SOKOS Viscous Liquid Filler: Automatic Piston Filling Machine

Engineered for Demanding Applications

Where This Piston Filler Excels

Problem-Solving Design for:

-

Pastes/Semi-solids (cosmetic creams, waxes)

-

Chunky formulations (salsas, dressings with >5mm particulates)

-

High-viscosity fluids (50,000+ cP adhesives, heavy oils)

Industry-Proven Performance:

Technical Evolution: Beyond “Obsolete” Piston Technology

How SOKOS Redefines Piston Filling?

Traditional Limitations Solved:

| Old Challenge | SOKOS Innovation |

|---|---|

| Mechanical volume adjustment | Touchscreen servo calibration (0.1s changeovers) |

| Particulate jamming | Oversized rotary valves (handles 8mm chunks) |

| Accuracy drift | Closed-loop feedback (±0.2% consistency) |

Key Differentiator:

*”While basic piston fillers decline, SOKOS integrates servo-driven precision with rugged particulate handling – delivering 800-5,000 BPH without servo displacement filler costs.”*

– SOKOS Engineering Team

Unmatched Specifications for Industrial Demands

Core Technical Architecture

| Subsystem | SOKOS Advantage | Competitive Edge |

|---|---|---|

| Drive System | Panasonic servo motors | 40% faster response vs. stepper motors |

| Control Interface | Schneider PLC + 10″ HMI | Store 200+ recipes with barcode recall |

| Hygienic Design | CIP-ready pipelines | Meets EHEDG Guideline 8 |

| Material Handling | Dual-jacketed heated hopper | Maintains 40°C±2°C for viscous products |

Critical Upgrades Available:

-

Nitrogen blanketing for solvents

-

Explosion-proof certification (IECEx)

-

3-A sanitary compliance package

Real-World Performance Metrics

Production Validation Data

Food Sector Application (Heavy Sauce):

-

Throughput: 4,200 BPH @ 500ml fills

-

Accuracy: ±0.5% over 8-hour run

-

Particulate Handling: Tomato chunks ≤6mm

Cosmetic Lab (Luxury Creams):

-

Viscosity: 35,000 cP

-

Container Adaptation: Jar switching in <15min

-

Yield Savings: $11,200/year vs. overflow fillers

Why Manufacturers Choose SOKOS?

The Operational Advantage Matrix

| Pain Point | SOKOS Solution |

|---|---|

| High product giveaway | Self-calibrating volume control |

| Cross-contamination risks | Quick-disconnect CIP pipelines |

| Downtime during changeovers | Tool-less nozzle swaps |

| Labor-intensive operation | “No bottle, no fill” automation |

Included Standard Features:

-

Anti-drip nozzles with suck-back

-

Bottle locator system

-

Production counter with OEE reporting

Technical Specifications

Precision Engineered Components

| Parameter | Specification |

|---|---|

| Filling Heads | 1-16 (modular expansion) |

| Volume Range | 100ml-5,000ml |

| Power | 2000W / 220VAC (380V optional) |

| Construction | 304SS frame, 316SS contact surfaces |

| Throughput | 800-5,000 BPH |

| Accuracy | ±0.2% (servo-controlled) |

| Dimensions | 2500×1400×2500mm |

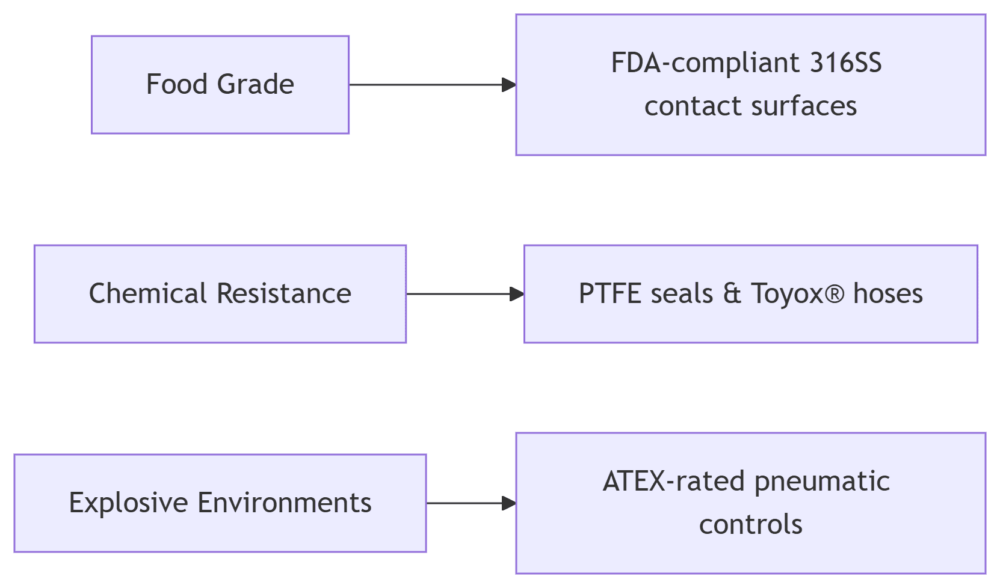

Industry-Specific Configuration Guide

For Chemical Packers:

-

PTFE-lined fluid paths

-

Conductive hoses for static dissipation

-

Hazardous area certification

For Food Producers:

-

USDA-approved seals

-

Double-jacketed heating (40-85°C)

-

Integrated CIP/SIP

Ready to Transform Your Line with a Viscous Liquid Filler?

Request Your Custom Solution:

[► Get Machine Configuration Proposal]

[► Schedule Live Demo]

Included with Every SOKOS Filler:

-

1-year comprehensive warranty

-

Remote diagnostics via IIoT gateway

-

On-site training for operators