Aluminum Bottle Filling & Capping Machine – A Breakthrough in Packaging Technology

High-Precision All-in-One Solution for Carbonated & Non-Carbonated Beverages

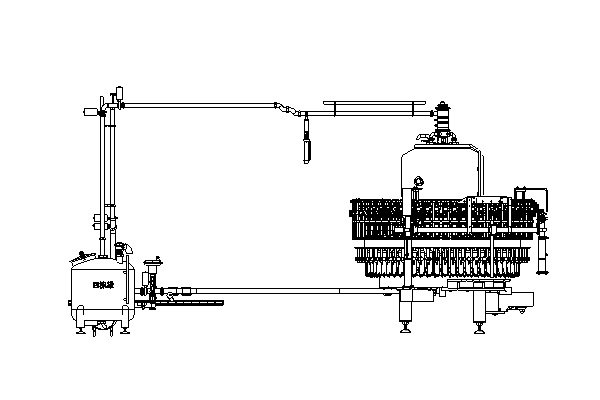

As a leading packaging equipment supplier, our company has pioneered the development of an advanced aluminum bottle filling and capping machine, addressing a critical gap in the domestic market. Designed for threaded aluminum bottles, this all-in-one system ensures high filling accuracy and reliable sealing, catering to both carbonated drinks and non-carbonated beverages like juices and functional drinks.

Features & Benefits

-

Versatile Configurations

-

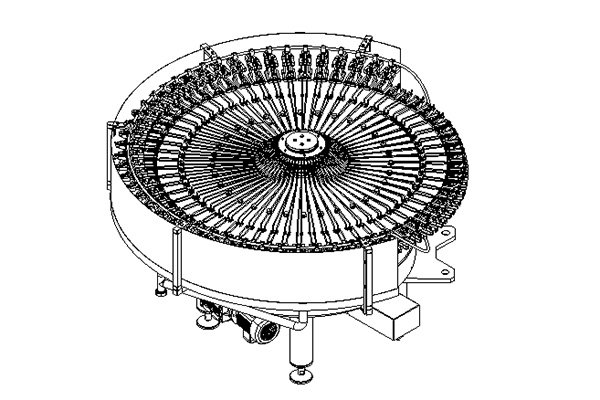

Standard model integrates three functions: bottle rinsing, filling, and capping.

-

Customizable as 2-in-1 or 4-in-1 systems based on production needs.

-

Utilizes screw-fed bottle conveyance with ultra-high molecular polyethylene star wheels for smooth operation.

-

-

Advanced Process Flow: Precision, Hygiene & Sealing Excellence

Our aluminum bottle filling and capping machine incorporates a meticulously engineered three-stage process to ensure optimal hygiene, filling accuracy, and leak-proof sealing. Each step is designed for maximum efficiency while maintaining the highest industry standards.

-

-

Bottle Rinsing: Automated Sterilization for Purity

Before filling, each aluminum bottle undergoes a thorough cleaning process to eliminate contaminants.

-

Flip-and-Spray Mechanism: Bottles are inverted 180°, allowing high-pressure RO water or sanitizing solution to rinse both the interior and exterior surfaces.

-

Gentle Handling: The ultra-smooth polyethylene star wheels and precision-guided nozzles prevent scratches while ensuring complete coverage.

-

Drainage & Drying: Excess liquid is filtered out automatically, preparing bottles for contamination-free filling.

-

-

Filling: Precision Dosing for Carbonated & Still Beverages

Our system supports multiple filling methods to accommodate different beverage types:

-

Carbonated Drinks (Isobaric Filling):

-

The bottle is pressurized with CO₂ to match the tank’s internal pressure before liquid is released.

-

A return gas tube prevents foaming and ensures consistent fill levels.

-

Post-filling, a controlled pressure release prevents sudden CO₂ loss.

-

-

Non-Carbonated Beverages (Gravity Filling):

-

Liquid flows naturally into the bottle, with sensors cutting off the flow precisely at the desired level.

-

Optional electronic filling valves provide ±0.5% accuracy for high-value products like juices and functional drinks.

-

-

-

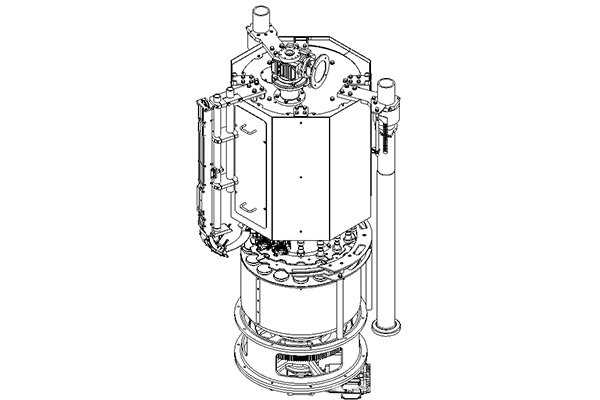

Capping: Secure, Tamper-Proof Sealing

The final stage guarantees airtight closure with industry-leading capping technology:

-

Servo-Driven Dual-Cam System:

-

A servo motor precisely controls rotation speed, ensuring uniform torque application.

-

Two-Stage Threading: The first cam pre-seats the cap, while the second applies final torque for a perfect seal.

-

-

Hang-and-Press Cap Placement:

-

Caps are automatically aligned and gently pressed onto bottles before threading.

-

Anti-Leak Verification: Sensors detect misaligned or missing caps, preventing defective packaging.

-

-

-

Why Choose Our Equipment?

-

Efficiency: Adjustable speed via frequency conversion motor.

-

Quality Assurance: Dual-sealing capping and leak-proof filling valves.

-

Smart Controls: Real-time fault alerts, no-cap detection, and production tracking.

Robust Design & Safety

-

-

High-strength carbon steel base with SUS304 stainless steel cladding.

-

Overload protection and automatic lubrication for longevity.

-

Imported components (sensors, PLCs, etc.) guarantee reliability.

-

Trusted by global packaging equipment supplier, our aluminum bottle filler sets new benchmarks in speed, precision, and adaptability. Contact us to elevate your production line with cutting-edge technology.