A Complete Guide to Bottled Water Success

Water plant business opportunities are surging globally, driven by rising demand for safe, convenient drinking water. The bottled water market alone is projected to reach $500 billion by 2030, with particularly strong growth in Tier-2/3 cities in emerging economies like India. This guide details every step to launch and scale your venture.

Steps to Start Your Own Bottled Water Business

-

Market Research and Business Planning:

Analyze local demand, competition, and pricing. For example, Tier-1 cities (e.g., Delhi) favor single-use bottles, while Tier-2/3 markets show higher growth for 20L bulk cans or pouches2. Define your unique angle—premium mineral water, affordable pouches, or customized corporate bottles. -

Company Registration and Branding:

Register your business entity (LLC/Corporation) and trademark your brand. In China, this involves:-

Name pre-approval

-

Capital verification (min. ¥500–800 registration fees)

-

Licensing from the Administration for Market Regulation.

-

-

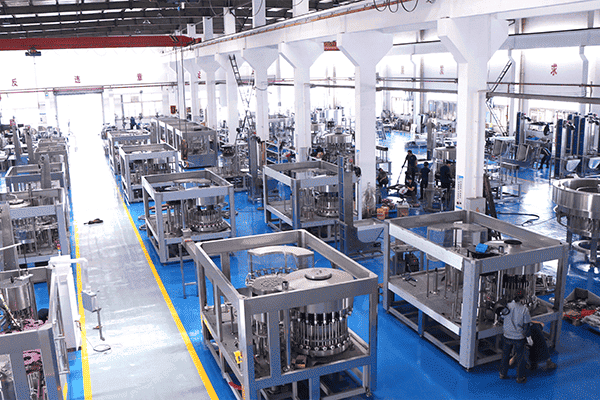

Location and Infrastructure Setup:

Secure a facility (≥400 m² for bottling plants) away from pollution sources. Install:-

Water treatment systems (RO/UV filters)

-

Filling/packaging machines

-

Sterilized bottling zones.

-

-

Distribution Network Development:

Adopt models like:-

Flat Distribution (e.g., Farmer Brothers’ direct retailer partnerships)

-

Multi-tiered Systems (e.g., Wahaha’s “United Sales” with bonded distributors)9.

Target high-density areas first—e.g., focus on Shanghai/Hangzhou if near Qiandao Lake like Nongfu Spring did initially.

-

How Do Water Bottling Machines Work?

Modern plants integrate automated systems for efficiency:

-

Treatment Stage: Raw water undergoes reverse osmosis (RO), UV sterilization, and mineralization.

-

Bottle Processing:

-

Rinsers: Invert bottles and spray hot water (via dual 4.5μm/0.45μm filters) to remove residues.

-

Fillers: Volumetric piston fillers dispense precise amounts (e.g., 500ml–20L).

-

-

Robotic Packaging: KR180 robotic arms (like those at EnglishMountain Water) handle 45-lb filled jugs:

-

Vacuum heads grip bottle necks

-

Conveyors rotate crates 180° for loading/unloading

-

Throughput: 20 bottles/minute with 70% labor reduction.

-

Legal Requirements for Bottled Water Businesses

Compliance varies by region but typically includes:

Table 1: Legal Requirements Across Key Markets

| Region | Licenses/Permits | Key Standards |

|---|---|---|

| UK/EU | Food Business Registration; Natural Mineral Water Source Approval | HACCP plans; CIP sanitization; FSA labeling rules4 |

| China | Food Production License (QS); Environmental Impact Assessment; Hygiene Permit | GB 17323 bottled water standards; 50m pollution-free zone58 |

| Egypt | NARDWWS License (LE50M annual fee); Source Validation | Fixed government pricing tiers (per m³) |

Critical universal requirements:

-

Water testing: Quarterly microbiological/chemical tests.

-

Labeling: Ingredients, source, BPA-free status.

-

Facility hygiene: ISO-certified clean rooms.

Water Treatment Company FAQ

Table 2: Top Water Business FAQs

| Question | Answer |

|---|---|

| Profit margin per bottle? | 15–30% for 500ml bottles; 40%+ for 20L bulk cans. |

| Essential staff? | 8–10 for small plants: Chemists, machine operators, sales reps. Health certificates mandatory. |

| Can I outsource production? | Yes—contract manufacturers handle filling if you secure brand licensing (e.g., in India’s Tier-3 cities). |

Cost Breakdown: Launching Your Water Brand

Table 3: Bottled Water Plant Startup Costs

| Expense Category | Estimated Cost | Details |

|---|---|---|

| Land/Building | $50,000–$500,000 | Higher in metros (e.g., Mumbai); lower in Tier-2 cities like Jaipur |

| Machinery | $120,000–$850,000 | Includes RO system ($30K), filler ($50K–$200K), robotic packer ($250K+) |

| Licensing/Admin | $1,000–$15,000 | Varies by region (e.g., Egypt: $1.6M LE ≈ $85K) |

| Distribution | $20,000–$100,000 | Vehicle fleet + initial retailer incentives |

Total water plant project cost: $200,000–$1.5M. Micro-plants (pouches/jugs) in India start at $18,000 for rural penetration.

The Roadmap to Profitability

Scale strategically:

-

Year 1: Target local markets—offices, gyms, schools—with bulk discounts.

-

Year 2–3: Expand geographically using “reverse tracing”: Ask retailers for distributor leads.

-

Marketing: Build consumption logic. Example: Wahaha used professors to endorse water safety; modern brands leverage social media “water wellness” campaigns.

With water scarcity affecting 40% of the global population, ethical sourcing and sustainability (e.g., recyclable bottles) now drive 65% of consumer decisions. Integrate these into your water bottling plant business plan to secure long-term viability.