Crafting Tomorrow’s Thirst Quenchers: The Science Behind Plant-Based Beverage Production

The Booming Landscape

The plant-based beverage market has exploded, projected to reach $66.5 billion by 2029 (Grand View Research). Driven by health-conscious consumers and sustainability demands, oat plant-based beverages lead with 60% market share, followed by almond plant-based beverages (25%) and emerging players like pea and coconut.

Raw Material Mastery: From Grain to Glass

Plant-based beverages begin with precision-sourced ingredients:

-

Oats/grains: Beta-glucan content >4% for creaminess

-

Nuts: Almonds with 20-25% oil content

-

Legumes: Non-GMO soybeans with 40% protein

Industry Insight: Leading plant-based beverage companies like Oatly and Califia Farms use proprietary enzyme blends to optimize yield and mouthfeel.

Three Pathways to Perfection: Oat Processing Technologies

(Based on Krones’ industrial frameworks)

Type 1: Finished Oat Base

For market agility

-

Process: Hydration of pre-hydrolyzed oat syrup

-

Pros: <60-day implementation | Use existing infrastructure

-

Cons: 30% higher ingredient costs vs raw oats

-

Best for: New entrants testing plant-based beverage trends

Type 2: Oat Flour Transformation

Balancing cost & control

-

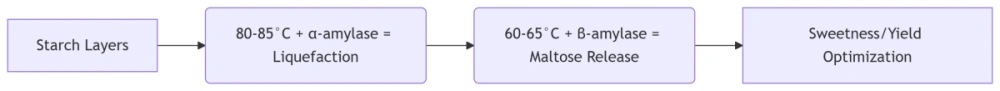

Hydrolysis: Custom enzymatic treatment (α-amylase @85°C → β-amylase @62°C)

-

Yield Boost: 15% higher solids extraction vs Type 1

-

Key Advantage: Formula independence from suppliers

Type 3: Whole Oat Engineering

Peak sustainability

-

Process: Direct milling of oat groats → In-line hydrolysis

-

Resource Savings: 40% less energy vs Type 1 (Journal of Food Engineering)

-

Output Quality: Superior β-glucan retention (98% vs 85% in Type 1)

Critical Process Innovations

Pre-Gelatinizer: The Clump Crusher

-

Swirl technology ensures perfect powder dispersion at 1:2 solid-liquid ratio

-

Prevents gelatinization before enzymatic reaction

Hydrolysis: The Flavor Decoder

Enzyme selection impacts:

-

Sweetness (maltose conversion)

-

Mouthfeel (dextrin chain length)

-

Yield (up to 92% starch utilization)

Separation & Fortification

-

Decanter Centrifuges: Remove 99.8% solids at 15,000 L/hr

-

Nutrient Fortification: Calcium phosphate, functional plant proteins, and plant pigments for food and beverages added post-separation

-

Stabilization: Gellan gum or locust bean gum for emulsion stability

Safety & Quality: Non-Negotiables

Microbial Control

-

Plant-based beverage E. coli testing: PCR diagnostics detect 1 CFU/25ml in <8hrs

-

Aseptic Processing:

-

UHT treatment: 140°C/4s → enzyme inactivation

-

Contipure AseptBloc fillers: 36,000 bottles/hr with 10-year sterility guarantee

-

Testing Protocols

-

Shelf-life validation: Accelerated studies at 38°C/90% RH

-

Nutritional profiling: HPLC analysis of protein/fat/sugar

Packaging: The Last Guardian

Aseptic carton fillers:

-

72,000 units/hr capability

-

<0.1% oxygen ingress (critical for organic beverage solutions)

-

Light-blocking layers protect sensitive plant pigments

The Future in Every Sip

As plant-based beverage brands innovate, expect:

-

Functional boosts: Adaptogens in healthy plant-based hot beverages

-

Process breakthroughs: AI-optimized hydrolysis saving 25% energy

-

Sustainability: Upcycled oat pulp in packaging

Technical Note: The plant-based food and beverage market will see 15.8% CAGR through 2030 (Mordor Intelligence), driven by continuous engineering refinements. From enzymatic precision to plant-based beverage testing rigor, science transforms humble grains into liquid gold.