Wine Production Technology: Mastering the Art of Bottling

Precision in Every Pour

Wine production blends tradition with cutting-edge technology. From fermentation to bottling, each step demands exacting standards. Modern wine filling equipment ensures consistency and quality in every bottle.

Core Wine Production Workflow

1. Fermentation & Aging

-

Grape crushing/must preparation

-

Primary/secondary fermentation

-

Barrel/bulk aging (months to years)

-

Filtration/clarification

2. Final Processing

-

Stabilization: Temperature control

-

Microfiltration: Microbial removal

-

SO₂ Adjustment: Oxidation prevention

-

Quality Control: Lab testing

The Bottling Revolution

Where craftsmanship meets automation

Critical Filling Methods

-

Inert Gas Shielding:

Nitrogen/argon blanketing prevents oxidation

Essential for premium wines -

Aseptic Filling:

Sterile environment for delicate varieties

Preserves subtle aromas

Equipment Spotlight

| Machine Type | Application |

|---|---|

| Automatic wine bottle filling machine | 2,000-12,000 bph capacity |

| Wine filling line | Integrated rinsing-filling-corking |

| 3-in-1 wine filling machine | Compact solutions for estates |

| Wine bottle filling equipment | Glass/PET versatility |

Key Technical Features

-

Precision flowmeters (±0.5% accuracy)

-

Touchless filling nozzles

-

Cork/screwcap compatibility

-

Integrated corkers/cappers

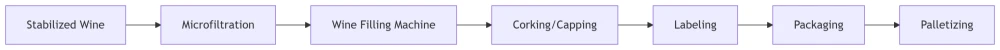

Production Flow Visual:

Industry Insights

-

Global wine filling machine market reaches $1.8B (2024)

-

Automatic wine filling machines dominate 85% commercial production

-

Key growth areas:

• Small wine filling machines (craft wineries +22% YoY)

• Aseptic wine filling lines (premium segment +15%) -

Top innovations:

» Laser-guided bottle positioning

» Self-cleaning filling heads

Sourcing Considerations

When selecting wine filling machinery:

-

Throughput: 500-15,000 bottles/hour options

-

Flexibility: Bottle size/screwcap adaptability

-

Hygiene: CIP/SIP compatibility

Leading suppliers: -

European precision engineers (Italy/Germany)

-

Cost-effective wine bottle filling machines from Asia

Quality Control Essentials

Modern wine filling equipment incorporates:

-

O₂ sensors (post-fill measurement <0.5ppm)

-

Fill height cameras (±1mm accuracy)

-

Automated rejection systems

-

Data tracking (bottle-level traceability)

Conclusion: Engineering Liquid Art

From fermentation tanks to the filling wine bottles stage, technology preserves winemaking heritage while ensuring consistency. Whether operating a small wine filling machine for limited editions or a full wine filling production line for global distribution, precision bottling remains the final safeguard of quality.