What is the process of liquid filling machine?

What is the process of liquid filling machine? Liquid Filling Machines: The Backbone of Modern Production Every day, countless bottles of drinks, medicines, and household

What is the process of liquid filling machine? Liquid Filling Machines: The Backbone of Modern Production Every day, countless bottles of drinks, medicines, and household

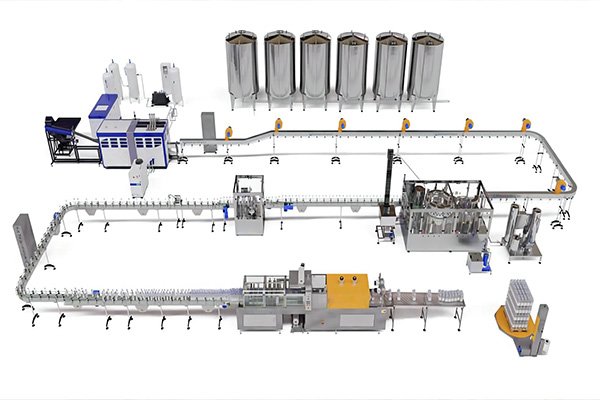

The global bottled water market is projected to reach $506 billion by 2030 (Grand View Research), driven by rising health consciousness and urbanization. Behind every

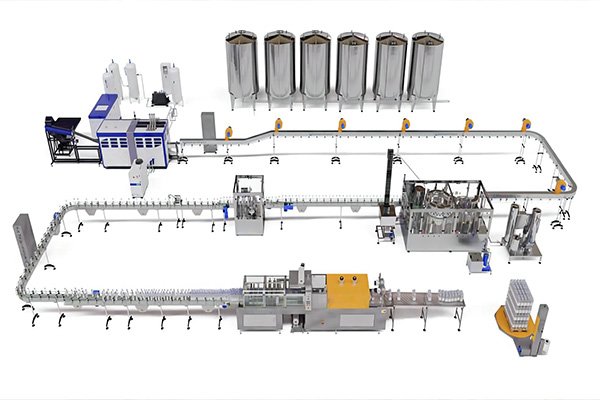

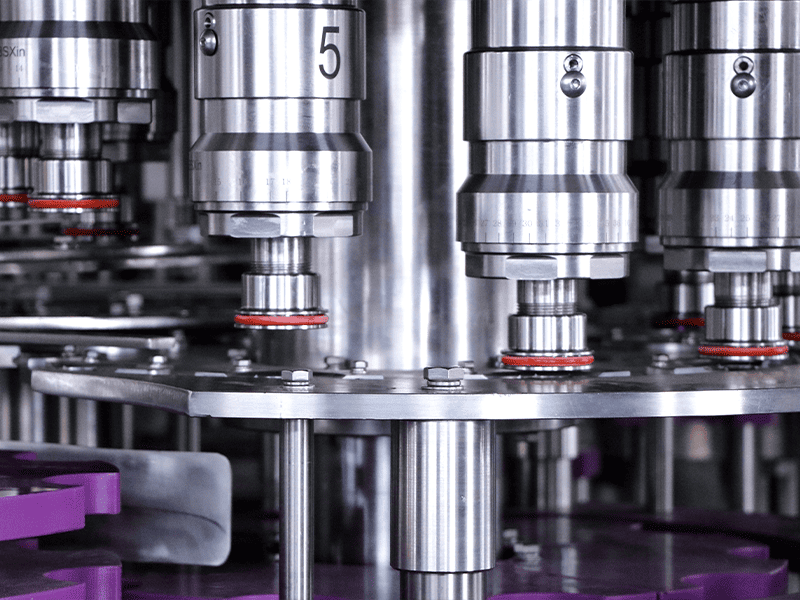

What is a Liquid Filling Machine? A Comprehensive Guide Introduction to Liquid Filling Machines A liquid filling machine is a mechanical device designed to fill liquid products

For mineral water plants and packaged drinking water producers, efficiency is measured in seconds per jar. The QGF-100 water jar machine delivers industrial-grade automation—processing 100

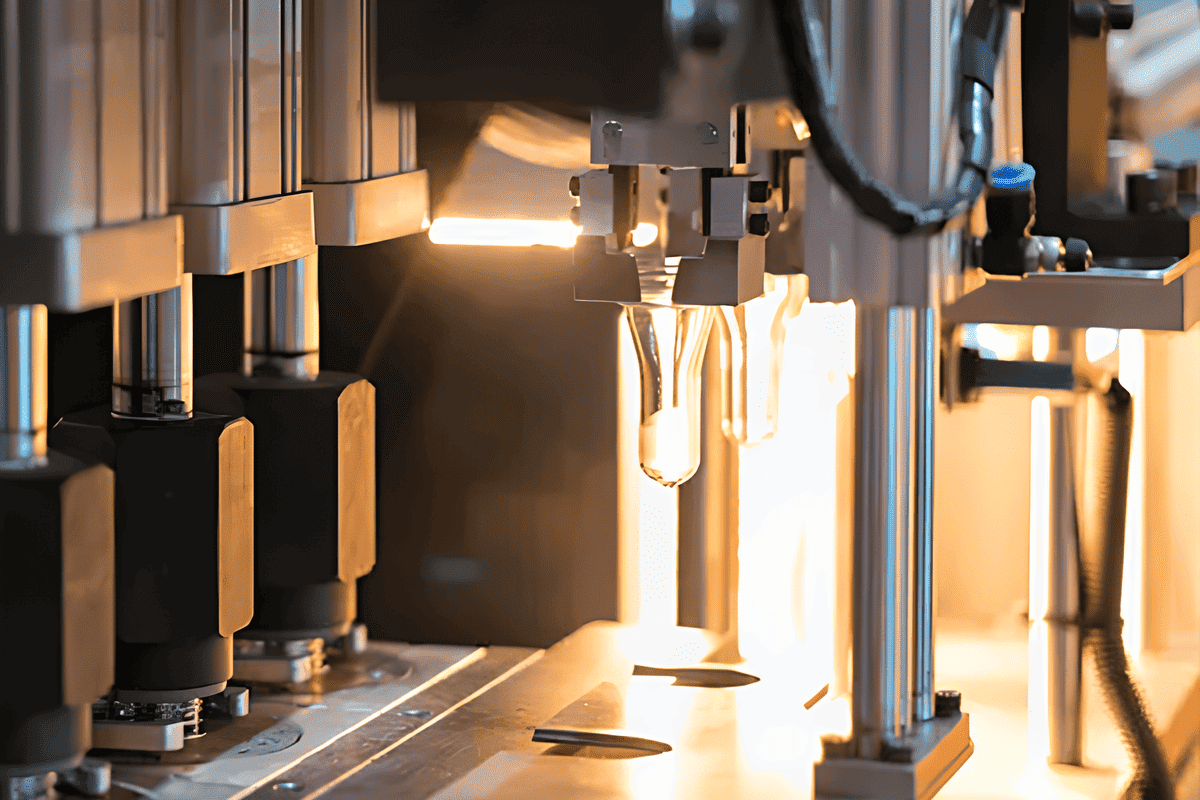

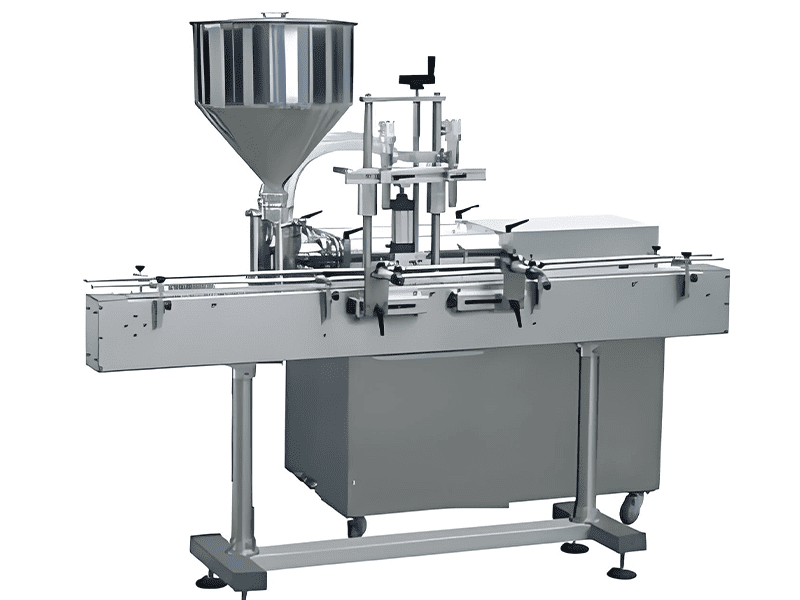

SOKOS Viscous Liquid Filler: Automatic Piston Filling Machine Engineered for Demanding Applications Where This Piston Filler Excels Problem-Solving Design for: Pastes/Semi-solids (cosmetic creams, waxes) Chunky

Volumetric Fully Automatic Liquid Filler: Engineering Precision for Industrial Packaging Volumetric liquid filler features advanced design for viscous liquids and hazardous materials. Core Advantages Driving

Automatic Liquid Filler Investment Guide: Semi-Automatic vs. Fully Automatic Price Analysis Core Price Ranges: From Entry-Level to Industrial Systems Semi-automatic models dominate the lower investment

Mastering Overflow Filling Machine: The Science of Perfect Liquid Levels Overflow Filling Machine Built for Precision and Consistency in Demanding Industries The Gravity Advantage: Core

We look forward to working with you who are visionary, capable, and market-savvy to jointly expand the blue ocean market of beverage machinery!