Precision & Sustainability in Modern Beverage Production

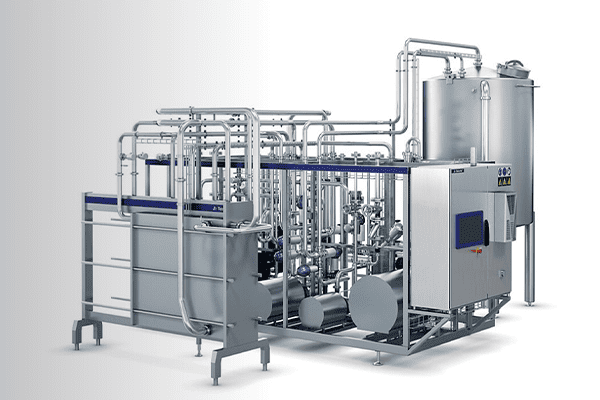

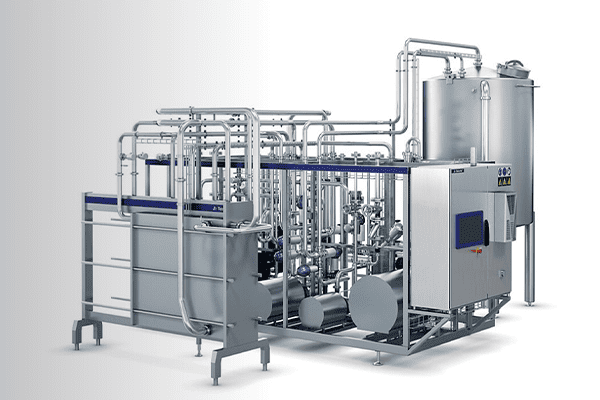

How Continuous Sugar Dissolution Saves 40% Energy with Precise Brix Control I. The Sugar Paradox: Balancing Dissolution Efficiency & Energy Costs Sugar dissolution accounts for 18-25% of

How Continuous Sugar Dissolution Saves 40% Energy with Precise Brix Control I. The Sugar Paradox: Balancing Dissolution Efficiency & Energy Costs Sugar dissolution accounts for 18-25% of

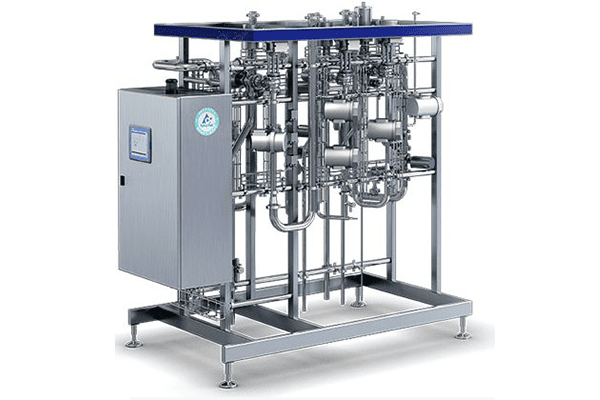

AI Fat/Protein Control for High Yield & Cost Efficiency I. The Science of Perfection: Modern Dairy Standardization Demystified In an industry where 0.1% fat deviation can impact

The ready-to-drink (RTD) market is exploding, with coffee and juice leading the charge. But here’s the thing: A traditional RTD Coffee Production Line that only

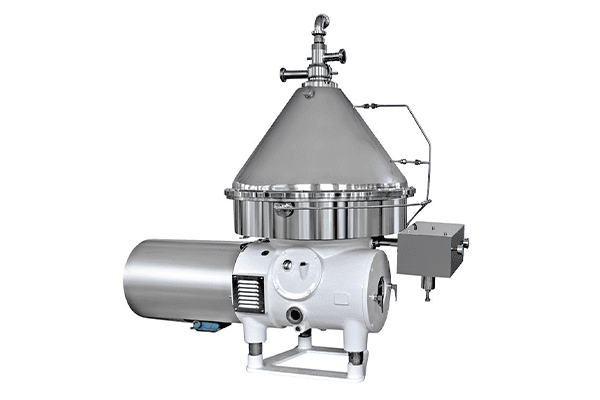

Next-Gen Centrifugal Tech for Purity & Waste Value I. The Separation Imperative in Modern Beverage Production With 72% of beverage manufacturers reporting increased demand for

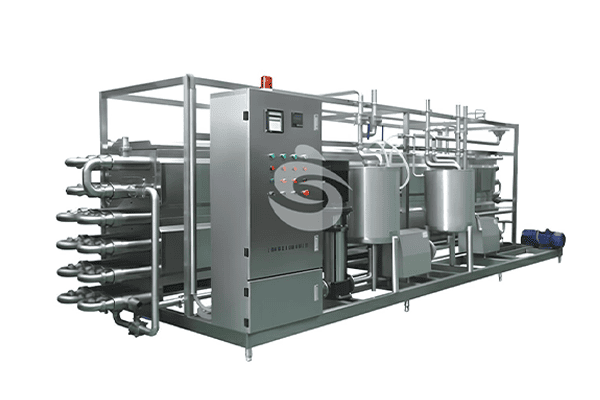

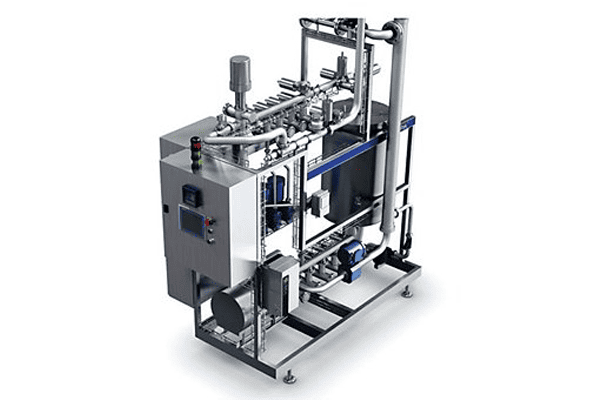

Pasteurization is often thought of as just a way to kill germs—but in modern food and beverage production, it’s so much more. It’s the secret

How to Achieve 20,000 BPH in Juice Bottling: A Step-by-Step Guide Reaching a 20,000 bottles-per-hour (BPH) output in Juice Filling Line is a major milestone for

Intelligent Mixing Hits 99.8% Uniformity with Zero Residue I. Mixing Process: Molecular-Level Precision Engineering in Beverage Production In beverage manufacturing, minor variations in mixing can

I. Cleaning in Place Technology: The Invisible Guardian of Beverage Production In beverage filling operations, equipment cleaning efficiency directly determines production line profitability. Traditional manual

We look forward to working with you who are visionary, capable, and market-savvy to jointly expand the blue ocean market of beverage machinery!