Automatic Liquid Filler Investment Guide: Semi-Automatic vs. Fully Automatic Price Analysis

Core Price Ranges: From Entry-Level to Industrial Systems

Semi-automatic models dominate the lower investment tier of the automatic liquid filler market:

-

Basic pneumatic units: $900–$4,800 for single-head machines handling 5–500ml fills (e.g., GF series with ±1% accuracy)

-

Mid-range configurations: $7,390–$15,000 featuring enhanced precision (±0.5%) and capacities up to 1,000ml

-

High-volume variants: $38,000+ for specialized viscous liquid fillers with heated hoppers

Fully automatic systems command premium pricing:

-

Standard production lines: $45,000–$100,000 for integrated filling-capping solutions (e.g., 200L syrup fillers at 60–120 containers/hour)

-

Pharma-grade systems: $110,000–$298,500 with GMP compliance, PLC controls, and outputs exceeding 20,000 BPH

-

Aseptic carbonated beverage lines: $120,000+ for ISO-certified machines with vacuum filling tech

What Drives the $100,000+ Price Gap?

Hardware & Performance Factors

| Component | Semi-Auto Cost | Fully Auto Cost |

|---|---|---|

| Automation | Manual container handling | Robotic positioning + vision systems |

| Speed | 10–50 BPM | 300–20,000 BPH 57 |

| Accuracy | ±0.5–1% | ±0.1% with flow meters 5 |

| Materials | 304 stainless steel | 316L stainless + CIP/SIP systems |

Engineering & Compliance

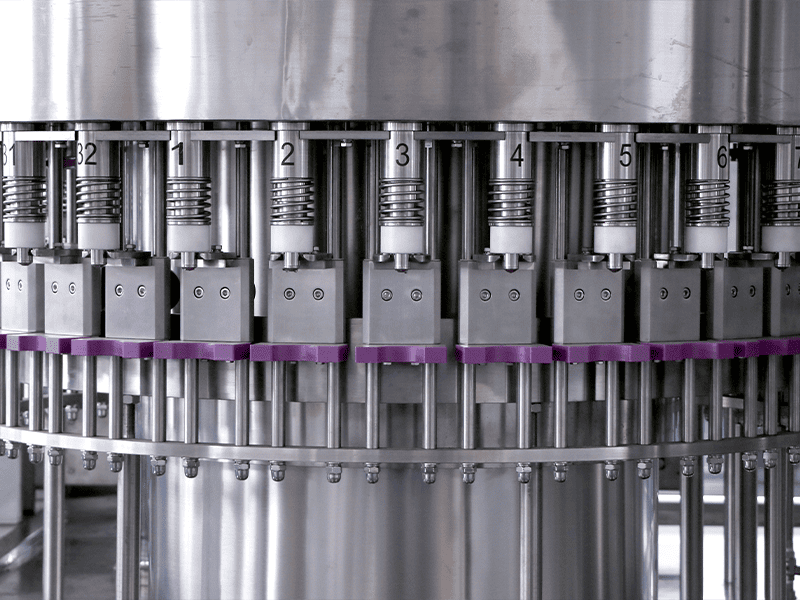

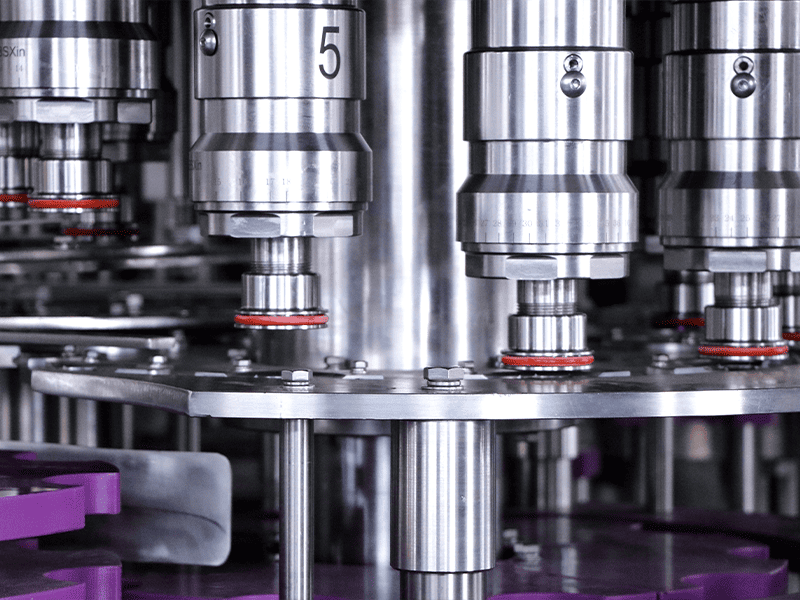

Fully automated Automatic liquid filler solutions incorporate:

-

Advanced controls: Mitsubishi PLCs, OMRON sensors, and HMI touchscreens 7

-

Certifications: CE, ISO 9001, FDA-compliant material traces 39

-

Modularity: Quick-change nozzles/cylinders for multi-product lines 6

Industry-Specific Cost-Benefit Analysis

Where Semi-Auto Wins (ROI < 12 Months)

-

Startups/Small batches: Cosmetic labs filling creams at 30 BPM need <$15k investment 9

-

Chemicals: Corrosion-resistant $9,000 pneumatic fillers for oils/adhesives 10

-

Changeover flexibility: Manual systems adapt to new containers in minutes 6

When Full Automation Pays Off

-

Beverage producers: $120k automatic lines achieve 9,000 BPH with <0.1% giveaway – paying back in 18 months via 24/7 runs 5

-

Pharma: $110k capsule fillers (800 pills/min) ensure ±3% dosage accuracy under GMP 2

Hidden Costs: Beyond the Sticker Price

-

Semi-automatic add-ons:

-

Labor: $20/hr operators for manual loading

-

Upgrades: $3k–$8k for stirrers/heaters for viscous products 1

-

-

Fully automatic overheads:

-

Utilities: 15–200kW power consumption 57

-

Maintenance: $5k–$15k/year for PLC/servo upkeep

-

Strategic Buying Guide

For Budgets <$50k:

-

Prioritize piston-based semi-autos like the GF-1000 ($15k; 1,000ml viscous fills) or Promake vertical fillers ($900–$4.5k) 69

For Outputs >5,000 Units/Day:

-

Invest in rotary Automatic liquid filler systems like ACE-Filling’s 18,000 BPH lines – expect 2–3 year ROI 5

Pro Tip: Always demand:

Machinery test reports and video inspections 13

1-year core component warranties (extend to 3 years for auto systems)

Future-Proofing Your Investment

Leading manufacturers now offer hybrid-ready semi-automatic fillers – upgradable with PLCs and auto-feed conveyors. Meanwhile, premium Automatic liquid filler solutions integrate IIoT for predictive maintenance, reducing downtime by 40% 78.

While semi-automatic fillers lower entry barriers (<$10k), high-volume producers must evaluate fully automatic systems’ throughput advantages. Calculate cost-per-filled-unit – not just machine price – to reveal true ROI.