Short Answer:

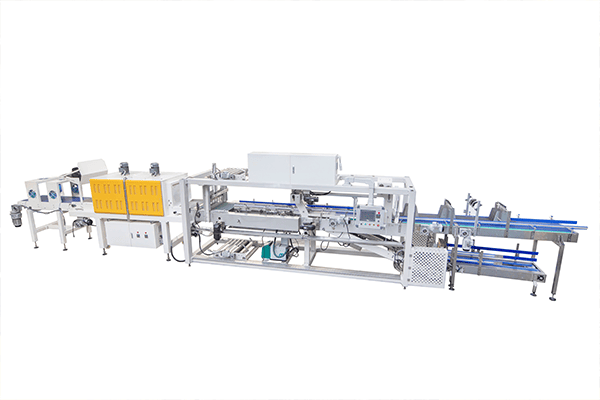

Automatic bottle packing machine prices range from $20,000 to over $200,000 — but the real cost depends on how you define value.

Breaking Down Price Tiers

| Machine Type | Price Range | Output Capacity | Key Applications |

|---|---|---|---|

| Entry-Level | $20,000–$50,000 | 500–2,000 btl/hr | Craft beverages, cosmetics |

| Mid-Range | $50,000–$120,000 | 2,000–8,000 btl/hr | Juice, sauce, pharmaceuticals |

| High-Speed Industrial | $120,000–$200,000+ | 8,000–30,000 btl/hr | Large beverage factories |

Data Source: 2024 Packaging Machinery Market Report (PMMI)

3 Core Factors Driving Costs

-

Automation Depth

-

Basic fill-seal units: $20k–$35k

-

Full lines (filling + capping + labeling + inspection): +$70k–$150k

-

Example: Adding AI vision inspection increases cost by 15% but reduces recall risk by 90%

-

-

Technical Specifications

-

Precision: ±0.5% filling accuracy systems cost 20% more than ±1.5% models

-

Material: Stainless steel (SUS304) construction adds $15k–$25k vs. aluminum

-

Speed: Every 1,000 btl/hr capacity increase raises price ≈$12k

-

-

Hidden Value Engineering

Superior bottle packing machine designs deliver ROI through:-

30% faster changeovers (e.g., servo-adjustable format parts)

-

50% less downtime (IoT-enabled predictive maintenance)

-

18% longer lifespan (over-engineered drive systems)

-

ROI Reality Check: Why Cheap Machines Cost More

Consider two scenarios for a 5,000 btl/hr operation:

| Metric | $45k Economy Machine | $110k Premium Machine |

|---|---|---|

| Upfront Cost | ✅ Lower | ❌ Higher |

| Labor Cost | $52k/year (3 operators) | $15k/year (0.5 operators) |

| Product Waste | 9% (leaks/misfills) | 0.8% |

| 5-Year TCO | $412k | $288k |

Source: McKinsey Packaging Automation Study 2023

Smart Buying Strategy

-

Demand TCO Modeling: Require OEMs to provide 5-year cost projections

-

Prioritize Modularity: Pay 10–15% extra for machines allowing future upgrades

-

Certifications Matter: FDA/CE-compliant bottle packing machines cost more initially but prevent $100k+ compliance fines

✦ Key Insight: The optimal machine isn’t the cheapest – it’s the one that minimizes cost per bottle packed over 10 years. Premium systems often achieve <$0.003/bottle vs. $0.012+ for budget options.

While entry-level systems start around $20,000, strategic operations should budget $80,000–$150,000 for a robust automatic bottle packing machine that delivers 24+ month ROI through labor savings, waste reduction, and uninterrupted production. Always evaluate suppliers on lifecycle value – not sticker price.

Packaging Machine Cost: A Key Consideration, But Not the Only One

It’s essential to keep this in mind:

“While cost matters, it should never be the sole factor when selecting the right packaging solution for your operation.”

Letting “sticker shock” guide your decision can be risky — it often leads to the common mistake of simply going with the cheapest option, which may not meet your long-term needs.