Buffer Equipment: The Strategic Link in Beverage Production

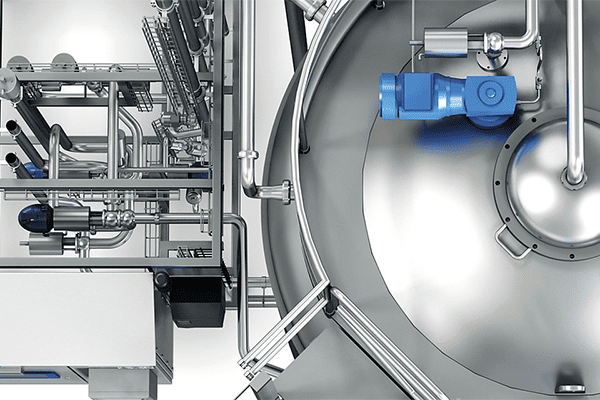

Behind the high-speed operation of beverage filling lines, where tens of thousands of bottles are filled per minute, lies a critical yet often overlooked component: buffer equipment. Serving as the intelligent hub connecting preprocessing, filling, and packaging processes, modern buffer systems have evolved from simple storage vessels to core equipment integrating precision control, aseptic protection, and smart management.

I. The Evolution of Buffering Equipment: From Passive Storage to Active Regulation

In traditional beverage production, buffer tanks merely provided temporary storage. The new generation of intelligent buffer equipment is reshaping workflows through three technological breakthroughs:

-

Dynamic Balancing System

Utilizing pressure sensing and flow control technology, this system dynamically adjusts the operational rhythm of upstream/downstream equipment. A juice producer reported a 37% reduction in idle time and annual energy savings exceeding ¥150,000 after implementation. -

Intelligent Temperature Control Matrix

Multi-zone independent temperature modules achieve ±0.5°C precision, ideal for temperature-sensitive products like dairy or fruit pulp beverages, extending shelf life by 30%-45%. -

Self-Cleaning Ecosystem

CIP (Clean-in-Place) and SIP (Sterilize-in-Place) programs meet ASME BPE standards (aseptic grade) and EHEDG-certified hygiene configurations, reducing transition time to one-third of traditional systems.

II. Solving Industry Pain Points: Five Value Dimensions of Buffering Equipment

1. Loss Control Expert

A three-tier buffering design (gravity + pneumatic + mechanical damping) limits product splashing loss to 0.05%. One carbonated beverage producer reduced annual syrup loss by over ¥800,000.

2. Efficiency Multiplier

Patented rotary diverter valves enable 8-channel parallel operations, handling up to 60m³/h to support 30,000 bottles/hour filling lines.

3. Quality Guardian

-

316L mirror-polished stainless steel (Ra ≤0.6μm)

-

ISO Class 6 cleanliness maintenance

-

Online turbidity monitoring with early warning

4. Flexible Production Enabler

Modular design allows rapid reconfiguration, switching between particulate-containing and pure liquid products in 2 hours, boosting utilization by 65%.

5. Smart Factory Interface

Industrial IoT gateways transmit 20+ parameters to MES systems, transitioning from “passive buffering” to “predictive regulation.”

III. Selection Guide: Tailored Solutions for Four Key Scenarios

| Application Scenario | Recommended Configuration | Core Technical Highlights |

|---|---|---|

| Aseptic Cold Filling | Aseptic buffer tank + dual-valve array | Peracetic acid sterilization, positive pressure maintenance |

| High-Viscosity Beverages | Cone-bottom tank + helical flow guide | Heated conical base prevents sedimentation |

| Pulp/Fiber-Containing Products | Wide-diameter tank + self-cleaning agitator | Variable-speed stirring (10-60rpm) |

| Multi-Product Lines | Multi-chamber system + quick-change modules | Physical isolation valves prevent cross-contamination |

IV. SOKOS Buffer Equipment: Technological Breakthroughs

As an industry benchmark, our solutions offer three innovations:

-

Zero-Dead-Zone Flow Design

CFD-optimized channels ensure 100% product flowability, even for oat-containing plant-based beverages. -

Energy Recycling System

Recovers 80% of cleaning water heat, reducing steam consumption by 40% (annual carbon offset equals 200 trees). -

Predictive Maintenance Platform

Vibration sensors + AI algorithms predict mechanical failures 14 days in advance, slashing maintenance costs by 60% and boosting OEE to 92.3%.

V. The Future: Intelligent Evolution of Buffering Equipment

-

Digital Twin Systems

3D modeling cuts virtual commissioning time by 70%. -

Autonomous Decision-Making

Edge computing enables self-optimizing buffering strategies. -

Sustainable Design

Modular construction achieves 85% recyclability.

Redefining the Art of Production Rhythm Control

In today’s “microsecond era” of beverage competition, buffer equipment transcends its traditional role, emerging as the core control unit of smart manufacturing systems. Choosing the right buffer solution is not just about equipment performance—it’s a strategic decision to build agile, efficient, and sustainable production ecosystems.