If you’ve ever wondered how fresh oranges, mangoes, or grapes turn into the bottled juice on your grocery shelf, the answer lies in juice filling lines. These coordinated systems handle everything from squeezing fruit to sealing the final package, ensuring every sip is safe, tasty, and consistent.

Types of Juice Filling Lines by Packaging

Not all juice containers are the same, and neither are the lines that fill them. Each packaging type demands specific equipment to keep juice fresh and ready to drink.

Plastic Bottle Juice Lines

Plastic bottles—especially PET ones—are everywhere for a reason: they’re light, unbreakable, and easy to transport. Juice filling lines for plastic bottles are built to handle these containers’ unique needs. For example, if the line uses hot filling (more on that later), the plastic must be thick enough to withstand high temperatures without warping.

Glass Bottle Juice Lines

Glass bottles are a favorite for premium juices, like artisanal apple or grape blends, because they don’t affect the juice’s flavor. But glass is heavy and fragile, so these filling lines need gentle conveyors and precise filling nozzles to avoid breakage. They often move a bit slower than plastic bottle lines but excel at preserving the juice’s quality.

Can Juice Lines

Cans are ideal for juices that need a long shelf life—think shelf-stable orange or tomato juice. Their airtight seal locks out light and oxygen, which can ruin flavor over time. Can filling lines are designed for speed, with machines that clean, fill, and seal cans in quick succession.

Aseptic Carton Lines

Cartons (like Tetra Pak or roof boxes) are popular for juices that skip preservatives. These lines work in super-clean environments: the cartons are sterilized first, then the juice is poured in without ever touching bacteria. This “aseptic” process lets juice stay fresh without refrigeration, making them perfect for on-the-go drinks. These lines are also eco-friendly, using less plastic than bottles.

Types of Juice Filling Lines by Fruit Type

Different fruits make different juices—and need different equipment to get there. A line that squeezes mangoes won’t work the same way as one that presses apples.

Mango Juice Lines

Apple Juice Lines

Grape Juice Lines

Other Fruit-Specific Lines

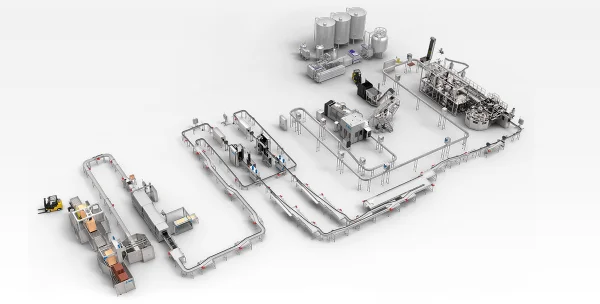

Key Equipment in Juice Filling Lines

Water Treatment Gear

Juicing Machines

Mixing Tanks

Filtration Tools

Deaeration Tanks

Sterilizers

- Tubular sterilizers: Good for thick, pulpy juices (like mango) that might clog other machines.

- Plate sterilizers: Faster and more efficient for clear juices (like apple).

Filling Machines

- Hot filling: Pours juice at around 85°C to kill bacteria, then seals the container while it’s hot to create a vacuum. If the juice cools below 85°C, the machine stops, sends the juice back to be re-sterilized, and starts again.

- Medium or cold filling: Uses less heat, which keeps more nutrients and flavor (great for organic juices). But these lines need super-clean rooms and special packaging to avoid bacteria.

Post-Filling Tools

- Inversion sterilizers: Flip bottles to sterilize the neck and cap.

- Coolers: Spray filled containers to bring them to room temperature.

- Dryers: Blow off extra water so labels stick.

- Labelers and coders: Add brand names, expiration dates, and barcodes.

- Cartoners: Pack bottles or cans into boxes for shipping.

Juice filling lines are busy, precise systems that turn fresh fruit into the drinks we love. Whether they’re filling plastic bottles, glass jars, cans, or cartons, each line is tailored to the juice’s needs—from the fruit it starts with to the package it ends up in.Have questions about packaging machines or need a custom line? Contact Sokos Machinery for free expert advice and tailored solutions.