Pasteurization is often thought of as just a way to kill germs—but in modern food and beverage production, it’s so much more. It’s the secret to keeping yogurt creamy for months, juice fresh without preservatives, and sauces safe to eat long after they’re made. And since every product is different (think thin juice vs. thick yogurt), one-size-fits-all systems just don’t cut it.

More Than Just Killing Germs: What Pasteurization Really Does

Today’s pasteurization systems have three big jobs, all working together:

- Keeping it safe: They kill 99.999% of harmful bacteria (that’s a 5-log reduction, meeting strict FDA and EFSA rules). No more worries about recalls from contaminated products.

- Making it last: Without pasteurization, fresh juice might go bad in a week. With the right process? It can stay fresh for 60 to 180 days. Yogurt, sauces, and even cold-pressed drinks get the same boost.

- Making it better: Heat can actually improve texture. For example, in yogurt, precise pasteurization denatures proteins to make it 30% thicker—so you can use fewer additives.

Our team looked at industry data, and here’s what we found: 88% of beverage recalls happen because the heat treatment wasn’t done right. But when pasteurization is tailored to the product, factories see 12-18% better yields.

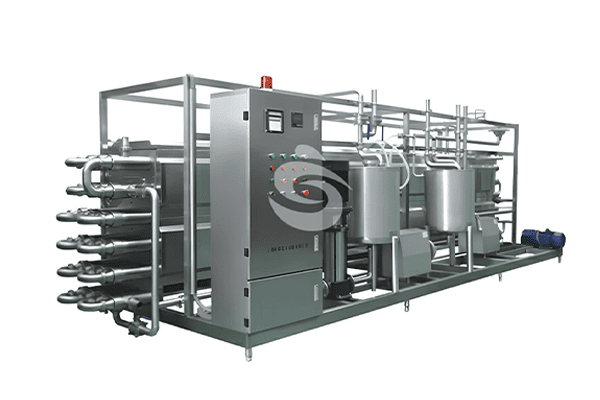

Why Most Factories Need Custom Pasteurization

Walk through any food plant, and you’ll notice no two products are the same. A runny lemon juice needs different heat than a chunky tomato sauce. That’s why 80% of the systems we build are custom. Here’s how we make them fit:

Smart Pressure Control

- Balanced pressure: We keep the pasteurized side of the system 0.2-0.5 bar higher than the raw side. This stops raw, unprocessed liquid from mixing with the clean stuff—critical for avoiding cross-contamination.

- Leak checks without the hassle: Our systems can spot tiny cracks in plates without taking anything apart. It’s 98% accurate, so you catch problems before they become big issues.

One multinational juice company tried this, and their risk of cross-contamination dropped by 73%. No more wasted batches, no more safety scares.

Safety First—But Without Wasting Money

Great pasteurization keeps products safe and keeps costs down. Here’s how we balance both:

Triple-Check Safety Systems

- Real-time temperature tracking: Sensors monitor heat within ±0.3°C—so you know every drop gets treated properly.

- Bacteria checks on the spot: ATP tests (a quick way to spot germs) flag issues if levels go above 0.1 RLU, so you fix problems before they hit shelves.

- Self-cleaning that works: The system integrates with CIP (clean-in-place) setups, using 3D sprayers to make sure every nook gets cleaned. No more manual scrubbing.

Traceability You Can Trust

Ever had to track a batch back to its source? Our systems make it easy:

- Plates are laser-etched with unique numbers (meeting EN 10204 3.1 standards) so you know exactly which parts touched which batch.

- Records are stored on a blockchain, so they’re unchangeable and easy to share with regulators (perfect for FDA 21 CFR Part 11 rules).

Real-World Wins: How Custom Pasteurization Solves Problems

Let’s look at how this works for real products:

Yogurt That Stays Creamy

A dairy plant struggled with inconsistent thickness—sometimes their yogurt was too runny, sometimes too thick (they wanted 2,500-3,000 cP).

Our fix: We set the pasteurizer to heat to 75°C for exactly 25 seconds, which denatures the casein proteins just right. Then we added a rapid cooling step (25°C per minute) to lock in the texture.

Result: They cut stabilizer use by 34%—saving money while making a smoother product.

Cold-Pressed Juice That Lasts

A juice company wanted their cold-pressed greens to stay bright and vitamin-rich, but they kept going bad in 2 weeks.

Our fix: We used flash pasteurization (95°C for 15 seconds) to kill germs fast, then blanketed the juice with nitrogen to push out oxygen (keeping levels below 0.5 ppm).

Result: The juice stayed fresh for 120 days, with 80% of its vitamin C intact—no preservatives needed.

Smart Systems That Get Smarter

Modern pasteurization isn’t just a machine—it’s a team player in your operation.

- AI that predicts problems: Algorithms watch for wear and tear, anticipating issues 90% of the time. No more unexpected breakdowns.

- Adapts to the day: If your raw juice is a little sweeter (Brix ±2%) or the factory is hotter (±5°C), the system adjusts automatically. No need for manual tweaks.

Ready for What’s Next?

Pasteurization is evolving, and your system should keep up:

- Digital twins: We build virtual copies of your setup to test changes (like new recipes) before you try them on the line—saving time and waste.

- Remote help: IoT sensors let our team diagnose issues from anywhere, cutting repair time by 65%.

- Greener options: Solar-thermal hybrids and biofilm-resistant surfaces mean 80% less chemical use—good for the planet and your budget.