Amidst an 18% annual growth in functional dairy demand, nutrient-fortified products have become a critical battleground for dairy manufacturers. However, industry pain points—such as over 60% probiotic inactivation and 40% vitamin loss—are hindering product innovation. As a 20-year expert in filling equipment R&D, we unveil how aseptic dosing technology breaks through these barriers.

I. Three Technical Bottlenecks in Traditional Processes

UHT dairy production has long faced triple challenges in adding heat-sensitive ingredients:

-

Thermal Damage Trap: Traditional batch processing requires dual high-temperature treatments (pasteurization + UHT), causing up to 52% loss of vitamin C.

-

Cross-Contamination Risks: Open storage systems increase microbial contamination risks by 3–5x.

-

Process Complexity: Multiple devices (heaters, pasteurizers, buffer tanks) occupy 40% more floor space.

II. Breakthroughs in Online Aseptic Dosing Technology

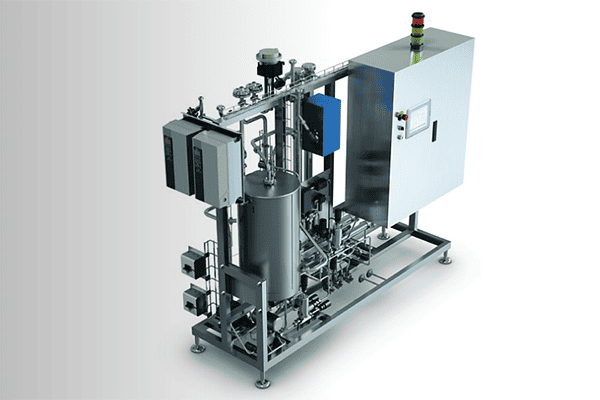

Our Sokos dual-technology solutions redefine online aseptic dosing:

Performance Comparison Table:

| Metric | Traditional Batch | Sokos F Solution | Sokos E Solution |

|---|---|---|---|

| Heat Treatments | 2 | 0 | 1 (filtration) |

| Floor Space | 100% | 60% | 55% |

| Ingredient Retention | 48%–65% | 92%+ | 85%+ |

| Microbial Control | 10 cfu/ml | 0 cfu/ml | <1 cfu/ml |

III. Sokos Dual-Technology Solutions Explained

-

Sokos Aseptic Dosing Unit F (Pre-Sterilized Transfer)

-

Double tube-sheet design ensures complete physical isolation.

-

0.1μm sterile barrier with 72-hour pressure retention.

-

Case study: A yogurt producer achieved 95% probiotic survival (vs. 58% previously).

-

-

Sokos Aseptic Dosing Unit E (Online Filtration)

-

Patented laminar flow filtration (pressure differential <0.02 MPa).

-

Smart CIP/SIP system reduces cleaning time to 15 minutes.

-

Case study: DHA oxidation in children’s milk powder dropped by 82%.

-

IV. Precision Solutions for 8 Key Ingredients

Based on 300+ client cases, our ingredient compatibility database reveals:

-

Enzymes: 99.3% rennet activity retention.

-

Probiotics: Bifidobacterium survival rate reaches 97.5%.

-

Vitamins: Vitamin C retention jumps from 65% to 91%.

-

Unsaturated Fats: Omega-3 peroxide value <0.5 meq/kg.

-

Minerals: Iron sedimentation reduced to 0.08%.

-

Natural Colors: Anthocyanin stability extends shelf life 3x.

-

Flavors: Aroma loss <2%.

-

Functional Extracts: 92% collagen activity retention.

V. Cost-Saving & Efficiency Case Study

A 100,000-ton/year dairy plant achieved:

-

35% lower CAPEX (eliminated pasteurization systems).

-

42% energy savings (no repeated heating).

-

99.6% product qualification rate (vs. 88.7% previously).

-

60% faster R&D cycles (flexible formulation adjustments).

As the dairy industry enters the “micronutrient era,” Sokos dual-technology solutions not only resolve heat-sensitive ingredient challenges but also enable seamless upgrades from traditional lines to smart factories. Our engineering team offers full-cycle services—from process design to system integration—to help manufacturers lead the functional dairy market.