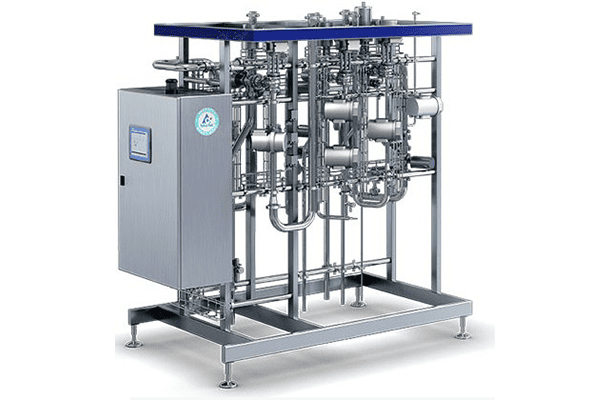

AI Fat/Protein Control for High Yield & Cost Efficiency

I. The Science of Perfection: Modern Dairy Standardization Demystified

In an industry where 0.1% fat deviation can impact product classification (e.g., whole vs. semi-skimmed milk), standardization systems determine profitability. Sokos’ technology achieves:

-

±0.05% fat content accuracy – 5x tighter than industry average

-

98.7% raw material utilization via closed-loop recovery

-

<2-minute formula for multi-product lines

Our 3-phase standardization process:

-

Separation: Centrifugal force at 8,000 RPM isolates cream (40-80% fat) from skim milk (<0.1% fat)

-

Dynamic Blending: PID-controlled recombination (flow rates: 5-50 m³/h)

-

Real-Time Verification: In-line NIR spectroscopy (1,200 data points/second)

II. Sokos’ Technological Edge: Beyond Basic Blending

1. Neural Network-Powered Precision

-

Adaptive Learning Algorithms: Compensate for:

-

Seasonal milk composition shifts (protein ±0.3%)

-

Plant-based fat globule variability (e.g., oat vs. almond)

-

-

Predictive Analytics: Forecasts batch outcomes with 97% accuracy

2. Multi-Component Standardization

| Parameter | Control Range | Applications |

|---|---|---|

| Fat Content | 0.1-50% | Milk, yogurt, ice cream |

| Protein | 2.8-5.2% | Greek yogurt, cheese |

| Solids Non-Fat | 8-12% | Evaporated milk, kefir |

3. Hygienic by Design

-

EHEDG-certified surfaces (Ra ≤0.8 μm)

-

CIP-optimized geometry (3D spray coverage >99%)

-

ASME BPE-compliant welds

III. Strategic Value Creation

1. Cost Optimization Engine

-

Yield Protection: Saves $18,000/year per 1% reduction in fat overuse

-

Energy-Smart Operation:

-

Variable frequency drives cut power use by 35%

-

Heat recovery from separation stage preheats incoming milk

-

2. Compliance Assurance

-

Automated documentation for:

-

FDA 21 CFR Part 120

-

EU Regulation 853/2004

-

HALAL/KOSHER certifications

-

-

Blockchain-enabled traceability (farm-to-processor FAT% verification)

IV. Application Spotlight

1. Greek Yogurt Production

-

Challenge: Achieving 9% protein consistently

-

Solution:

-

Ultrafiltration integration (30 kDa membranes)

-

Retentate recycling loop

-

-

Result: 22% higher protein recovery

2. Plant-Based Milk Blending

-

Challenge: Stabilizing almond milk emulsion (target: 3.5% fat)

-

Solution:

-

High-shear homogenization (250 bar) post-standardization

-

Lecithin dosage synchronization

-

-

Outcome: 60-day shelf life without sedimentation

V. Smart Control Architecture

1. Centralized HMI Dashboard

-

Monitors 50+ parameters including:

-

Phase inversion risks

-

Valve actuation response times

-

Energy intensity per liter

-

2. Edge Computing Modules

| Function | Benefit | Technical Specs |

|---|---|---|

| Anomaly Detection | 90% early fault identification | 10ms response latency |

| Recipe Management | Stores 1,000+ formulations | Cloud sync capability |

| Sustainability Audit | Tracks CO₂/water per batch | GRI Standards compliant |

VI. Future-Forward Standardization

-

Bio-AI Sensor Fusion

-

CRISPR-based protein analysis (30-second detection)

-

Machine vision fat globule sizing (0.1μm resolution)

-

-

Circular Economy Integration

-

Byproduct valorization:

-

Whey → Lactose extraction

-

Excess cream → Butter powder production

-

-

-

Decentralized Processing

-

Mobile standardization units for farmgate operations

-

Solar-powered compact systems (10 m³/day capacity)

-

VII. ROI Calculator: Quantifying Your Advantage

Example: Medium-Scale Dairy Plant (100,000 L/day)

| Metric | Conventional System | Sokos System | Delta |

|---|---|---|---|

| Fat Loss | 1.2% | 0.3% | +$540,000/year |

| Energy Cost | $0.18/L | $0.12/L | -$2.2M/year |

| Product Recalls | 2.1% | 0.4% | -$1.8M/year |

Standardization as Competitive Leverage

With 73% of dairy processors prioritizing “precision automation” (Dairy Foods 2023), Sokos systems transform standardization from a compliance step to a profit multiplier. Our Free Process Gap Analysis identifies:

-

Hidden raw material losses

-

Underutilized byproduct streams

-

Regulatory exposure points