How Continuous Sugar Dissolution Saves 40% Energy with Precise Brix Control

I. The Sugar Paradox: Balancing Dissolution Efficiency & Energy Costs

Sugar dissolution accounts for 18-25% of total energy consumption in sweetened beverage production. Traditional batch systems face two critical challenges:

-

Temperature Collapse: Adding 1kg sucrose to water at 80°C drops temperature by 6.2°C

-

Brix Variability: Manual methods exhibit ±2°Brix fluctuations vs. ±0.1°Brix in automated systems

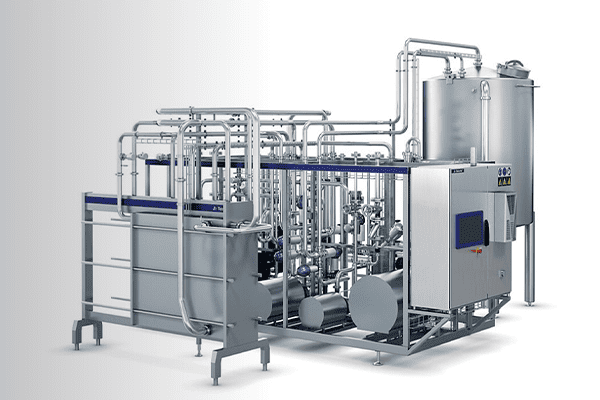

Sokos’ continuous dissolution technology resolves this through:

-

Dynamic Thermal Compensation – Maintains ±0.5°C of target temperature

-

Mass Flow Precision – Dosing accuracy of 0.25% CV (coefficient of variation)

-

Energy Recovery – 65% heat reuse through countercurrent heat exchangers

II. Core Innovations in Continuous Sugar Dissolution

1. Intelligent Feed Control System

| Parameter | Control Range | Technology | Benefit |

|---|---|---|---|

| Sugar Feed Rate | 50-5,000 kg/h | Loss-in-weight feeders | ±0.5% mass accuracy |

| Water Temperature | 60-95°C | PID-controlled steam | 0.3°C stability |

| Dissolution Time | 45-180 seconds | Variable screw conveyors | 98% sucrose conversion |

2. Closed-Loop Brix Management

-

In-line Refractometers: 0.01°Brix resolution with 10ms response

-

AI-Powered Adjustment: Compensates for:

-

Raw sugar moisture variance (0.5-1.2%)

-

Water hardness fluctuations (50-500 ppm)

-

-

Case Study: Reduced syrup waste by 32% in carbonated drink production

III. Energy-Smart Architecture

1. Thermal Optimization Matrix

| Component | Innovation | Energy Saving |

|---|---|---|

| Preheating Stage | Plate heat recovery | 25% reduction |

| Dissolution Chamber | Vacuum-assisted dissolution | 15% faster |

| Cooling Loop | Absorption chiller integration | 40% less power |

2. Carbon Footprint Reduction

-

Solar Thermal Option: 80% renewable heat contribution

-

Waste Steam Utilization: Reclaims 3.5 MJ per ton of syrup

-

LEED-compliant Design: 30% lower embodied carbon vs. conventional systems

IV. Application-Specific Solutions

1. High-Viscosity Applications (e.g., Milk Tea)

-

Challenge: Dissolving 65°Brix in <90s without caramelization

-

Solution:

-

Multi-stage shear mixing (10,000 s⁻¹)

-

Nitrogen blanketing to prevent oxidation

-

-

Outcome: 99.8% dissolution efficiency

2. Cold Fill Ready-to-Drink Teas

-

Challenge: Achieving 12°Brix at 4°C without crystallization

-

Solution:

-

Cryogenic dissolution (-5°C process)

-

Nanofiltration for micro-crystal removal

-

-

Result: 180-day shelf-life stability

V. Optimize Sugar Dissolving with a Smart Control Ecosystem

1. Centralized Process Dashboard

-

Monitors 20+ parameters including:

-

Real-time energy intensity (kJ/kg)

-

Sugar solubility index

-

Microbial risk alerts

-

2. Predictive Maintenance Suite

| Function | Technology | Impact |

|---|---|---|

| Wear Prediction | Vibration analytics | 90% failure anticipation |

| Nozzle Optimization | Machine vision | 50% longer component life |

| Sanitation Tracking | ATP surface monitoring | 3D CIP efficacy verification |

VI. Future-Ready Sugar Processing(Sugar dissolving)

-

AI Recipe Generation

-

Auto-adaptation to alternative sweeteners (stevia, allulose)

-

Predictive viscosity modeling

-

-

Blockchain Traceability

-

Farm-to-dissolver sugar provenance

-

Carbon credit certification

-

-

Zero Liquid Discharge

-

100% water recycling through reverse osmosis

-

Sugar dust recovery >99.9%

-

VII. ROI Analysis: Manual vs. Automated Systems

Scenario: 10-ton/hour Beverage Line

| Metric | Batch System | Sokos Continuous | Annual Saving |

|---|---|---|---|

| Energy Cost | $18.50/ton | $11.20/ton | $584,000 |

| Sugar Waste | 2.1% | 0.3% | $326,000 |

| Downtime | 8 hours/month | 1.5 hours/month | $240,000 |

Sweetening the Bottom Line

As beverage producers face simultaneous pressure to cut costs (energy prices up 35% since 2020) and improve quality (78% consumers demand consistent sweetness), intelligent dissolution systems become strategic imperatives. Sokos’ Free Energy Audit Program identifies:

-

Hidden sugar loss hotspots

-

Underutilized thermal recovery potential

-

Sweetener flexibility opportunities