What are the different types of filling machines?

The Ultimate Solution for Food, Pharma, and Industrial Liquid Packaging

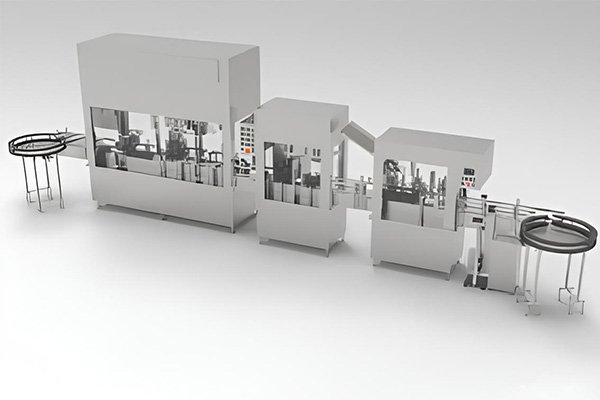

Sokos Liquid Filling machine is essential for accurately and hygienically packaging liquid products across industries such as food, pharmaceuticals, chemicals, and cosmetics.

1. Types of Liquid Filling Machines

1.1 By Filling Principle

-

Atmospheric Filling Machines

-

Uses gravity flow for low-viscosity, non-carbonated liquids (e.g., milk, wine).

-

-

Pressure Filling Machines

-

Ideal for carbonated beverages (e.g., beer, soda) with two subtypes:

-

Isobaric Filling (equal pressure)

-

High-Pressure Filling (for effervescent drinks).

-

-

-

Vacuum Filling Machines

-

Best for thick liquids (e.g., oils, syrups) by creating low-pressure conditions.

-

1.2 By Automation Level

-

Fully Automatic Liquid Fillers

-

PLC-controlled, high-speed (200+ bottles/minute), ideal for large-scale production.

-

-

Semi-Automatic Fillers

-

Manual bottle placement, cost-effective for small batches.

-

1.3 By Liquid Type

-

Dilute Liquid Fillers – For beverages, juices.

-

Viscous Liquid Fillers – For sauces, creams.

-

Oil Fillers – Specialized for lubricants & edible oils.

2. Key Applications of Liquid Filling Machines

2.1 Food & Beverage Industry

-

Bottling oils, sauces, vinegar, dairy, and alcoholic/non-alcoholic drinks.

2.2 Pharmaceutical & Cosmetics

-

Precision filling of medicines, serums, lotions, and shampoos.

2.3 Chemicals & Industrial Liquids

-

Packaging solvents, adhesives, paints, and lubricants.

2.4 Household & Agri-Products

-

Detergents, pesticides, and fertilizers.

3. Why Choose Sokos Liquid Filling Technology?

3.1 High Accuracy & Speed

-

±0.5% filling accuracy, up to 400 containers/minute.

3.2 Hygienic & Durable Design

-

316L stainless steel, CIP (Clean-in-Place) compatibility.

3.3 Customizable Solutions

-

Adaptable for bottles, cans, pouches, and barrels.

4. Selecting the Right Liquid Filling Machine

4.1 Production Volume

-

Low (≤1,000 units/hr) vs. high-capacity (20,000+ units/hr).

4.2 Viscosity & Foam Sensitivity

-

Non-foaming nozzles for carbonated drinks; piston fillers for thick pastes.

4.3 Compliance & Safety

-

FDA, CE, and GMP certifications for food/pharma use.

5. Future Trends in Liquid Filling

-

Smart Sensors – Real-time volume adjustments.

-

Sustainable Packaging – Reduced material waste.

-

IoT Integration – Remote monitoring & predictive maintenance.

Conclusion

Whether for beverages, chemicals, or cosmetics, a liquid filling machine boosts efficiency and consistency. Sokos Liquid Filling systems stand out for their precision, durability, and adaptability.