To guarantee quality in the modern beverage industry, aseptic filling technology is very crucial. This article aims to detail the working principles, innovative designs, and key components of professional-grade aseptic fruit juice filling equipment or a Fruit Juice Filling Machines, focusing on efficiency and sanitation as the basis of packaging.

I. Machine Composition & Working Principle

1. Key Structural Elements

- The aseptic particulate juice filler mainly includes:

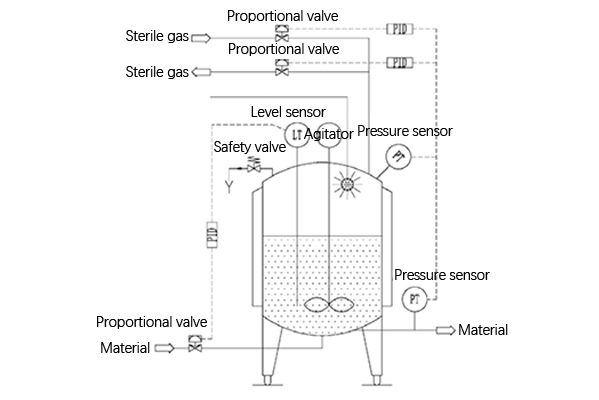

- Filling tank: with sterile agitation system, floor-mounted version

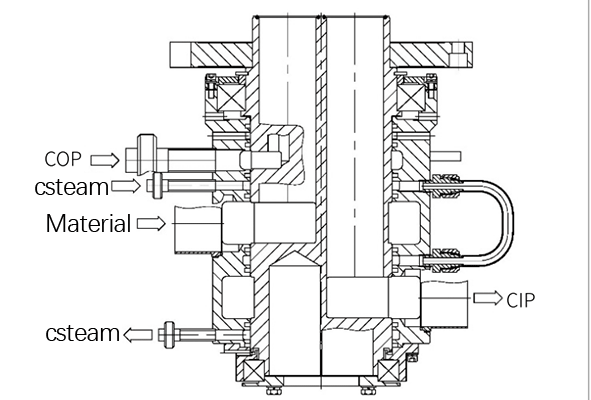

- Liquid distributor: Single-spindle construction for easy maintenance

- Filling pipeline: Specially designed S-shaped feed pipe

- Gas pipeline system: Precise sterile gas pressure regulation

- Filling valve assembly Innovative dual-valve design

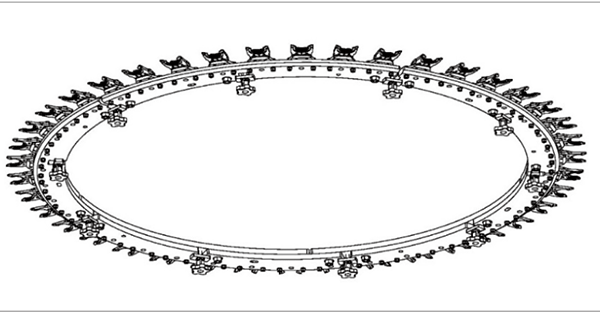

- Quick-change filling clamps: Ensuring flexibility in the filling line.

2. Intelligent Filling Process

These sterile filling stages employ advanced liquid-seal isolation technology in the Fruit Juice Filling Machines:

-

Pretreatment Phase:

- Dummy cup sealing test

- CIP/SIP system circulation (60-min chemical wash + 30-min 130°C steam sterilization)

- COP/SOP environmental disinfection

-

Filling Control Phase:

- Agitator maintains the homogeneity of the particles

- Real-time level sensor monitoring

- Sterile gas pressure precision adjustment: 0.1bar accuracy

- Non-contact filling: 3-5 mm valve-to-bottle distance

-

Quality Assurance:

-

- Flow meter dynamic calibration: ±0.5% accuracy

- Anti-drip design (0.2mm valve clearance)

- Pressure relief safety valve

II. Four Technological Innovations

1. Patented S-Shaped Feed Pipe

- Flow control: 8-12 mm adjustable diameter for different sizes of particles

- Hygienic advantage: Full-gradient drainage and no residual dead zones

- Pressure stability: Reduces flow fluctuation to within ±2%

2. Dual-Valve Coordination System

| Parameter | Diaphragm Valve | Filling Valve |

|---|---|---|

| Response Time | <50ms | <30ms |

| Seal Material | PTFE Membrane | 316L Stainless Steel |

| Service Life | 500,000 cycles | 1M cycles |

3. Non-Contact Filling Advantages

- Improved hygiene: Avoids bottle mouth infection

- 15% more productivity: Greater effective filling angle

- Universal compatibility: Adapts to PET/glass containers

1. Aseptic Filling Tank

- Capacity: 500-2000L options

- Features:

- Magnetic agitation (0-60rpm variable speed)

- Triple safety: Pressure sensor + mechanical valve + electronic interlock

- Mirror polish (Ra≤0.4μm)

2. Liquid Distributor

- Modular design includes:

- Product channel (φ50mm)

- CIP return line (φ40mm)

- Continuous steam barrier (0.3bar protection)

3. Valve Assembly

- Technical parameters:

- Speed: 100-150 bottles/minute

- Accuracy: ±1ml (static), ±3ml (dynamic)

- Material: FDA-certified 316L stainless steel

IV. Industrial Applications

This fruit juice filling machine is ideal for:

- NFC juice production

- Particulate beverages (≤8mm particles)

- Preservative-free products

- UHT-treated beverages

Case studies that have been documented demonstrate:

- 20% higher filling efficiency

- Product reject rate less than 0.3%

- Changeovers in 15-minute format