What is the process of liquid filling machine?

Liquid Filling Machines: The Backbone of Modern Production

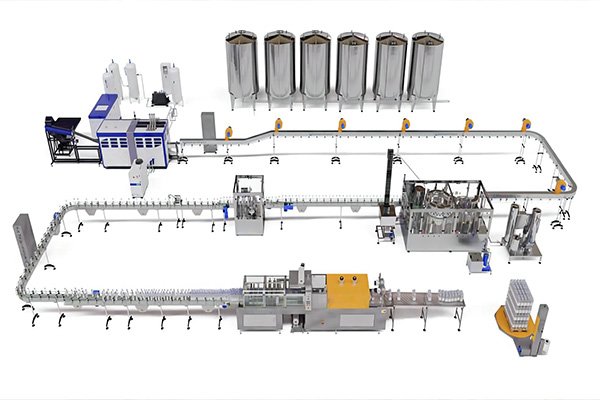

Every day, countless bottles of drinks, medicines, and household products make their way to store shelves – and nearly all of them pass through sokos liquid filling line. From your morning orange juice to the shampoo in your shower, these machines handle liquids of all types with remarkable precision.

1. Atmospheric (Gravity) Filling

How It Works

Atmospheric filling relies on gravity to transfer liquid into containers. The liquid flows freely from a storage tank into bottles or jars without external pressure.

Best For

-

Low-viscosity, non-carbonated liquids (e.g., water, milk, juice, alcohol, vinegar).

-

Products sensitive to pressure changes.

Advantages

✔ Simple machine design & low maintenance.

✔ Gentle filling, ideal for fragile liquids.

✔ Cost-effective for small to medium production.

2. Isobaric (Counter-Pressure) Filling

How It Works

The container is pressurized with CO₂ or nitrogen to match the storage tank’s pressure. Liquid then flows smoothly, minimizing gas loss and foam.

Best For

-

Carbonated drinks (beer, soda, sparkling water).

-

Products requiring extended shelf life.

Advantages

✔ Preserves carbonation & prevents oxidation.

✔ High-speed filling for large-scale production.

✔ Reduces foaming and spillage.

3. Vacuum Filling

Two Variations:

A. Differential Vacuum Filling

-

The container is evacuated while the storage tank remains at atmospheric pressure.

-

Liquid flows due to the pressure difference.

B. Gravity Vacuum Filling

-

Both the container and storage tank are vacuum-sealed.

-

Liquid moves by gravity in a low-pressure environment.

Best For

-

Viscous liquids (sokos liquid filling line oils, syrups).

-

Oxygen-sensitive products (juices, vitamin-enriched drinks).

-

Hazardous liquids (pesticides, chemicals).

Advantages

✔ Extends shelf life by reducing oxygen exposure.

✔ Minimizes leaks and evaporation.

✔ Safer for toxic or volatile substances.

4. Pressure Filling

How It Works

Mechanical or pneumatic pressure forces thick liquids into containers.

Best For

-

High-viscosity products (ketchup, toothpaste, cosmetics, meat paste).

-

Some carbonated drinks (fast-fill method).

Advantages

✔ Handles thick, sticky substances efficiently.

✔ Faster than gravity-based methods.

✔ Reduces product waste.

5. Siphon Filling

How It Works

A siphon tube creates suction to transfer liquid. Rarely used today due to inefficiency.

Best For

-

Small-batch, low-tech applications.

-

Historical or niche production methods.

Choosing the Right Liquid Filling Machine

Selecting the best method depends on:

✅ Viscosity – Thin vs. thick liquids.

✅ Carbonation – Whether the product contains gas.

✅ Sensitivity – Oxidation, flavor retention, and safety requirements.

✅ Production Speed – High-volume vs. small-batch needs.

For example:

-

Beer & soda → Isobaric filling (preserves carbonation).

-

Juices & dairy → Vacuum filling (reduces oxidation).

-

Toothpaste & sauces → Pressure filling (handles thickness).