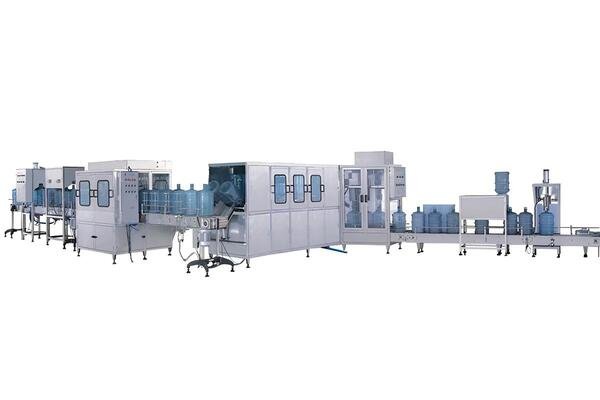

Complete Guide to Bottled Water Production Line: Components & Key Considerations

Efficient & Hygienic Solutions for 3-5 Gallon Bottled Water Filling

As a leading manufacturer of bottled water filling machine, we provide turnkey production lines for 3-gallon, 5-gallon (18.9L), and large-capacity bottled water.

1. Bottled Water Specifications & Market Varieties

Bottled water types (e.g., purified, mineral, alkaline) require tailored production approaches:

-

Source Water: Groundwater (natural springs) vs. treated municipal water.

-

Capacity: Standard 3/5-gallon sizes; customizable for high-volume outputs.

-

Compliance: Meets FDA/CE hygiene standards for safe consumption.

2. Key Components of a Bottled Water Production Line

A fully automated system includes:

A. Pre-Cleaning & Inspection

-

Automatic Decapper: Removes lids from recycled bottles; uses airflow to sort reusable caps.

-

Leak Detector: Pressurizes bottles to identify cracks (critical for large-scale operations).

-

Internal/External Brush Washers: Rotating brushes + high-pressure nozzles clean all surfaces.

B. Filling & Sealing

-

Bottled Water Filling Machine: Integrates disinfection, rinsing, filling, and capping.

-

8-Step Sterilization: Hot/Cold disinfectant sprays + purified water rinses.

-

Zero-Waste Design: Overflow water recirculates to storage tanks.

-

-

Online Cap Sanitizer: Automatically cleans caps with UV/disinfectant sprays.

C. Post-Production

-

Visual Inspection Station: Manual QC for contaminants.

-

Automatic Sleeving & Shrink-Wrapping: Steam seals neck films for tamper evidence.

-

Palletizing Robot: Stacks finished products with precision.

3. Critical Considerations for Production Efficiency

-

Hygiene: Use FDA-grade sanitizers and closed-loop cleaning systems.

-

Scalability: Modular designs allow capacity upgrades (e.g., from 300 to 900 BPH).

-

Energy Savings: Opt for servo-driven motors and heat-recovery steam systems.

Why Choose Our Bottled Water Filling Solutions?

-

Turnkey Service: From equipment supply to installation support.

-

Smart Automation: Reduces labor costs by 40% vs. manual lines.

-

Durable Build: Stainless steel construction with CIP/SIP compatibility.

Contact us to customize a production line for your water type and output needs!