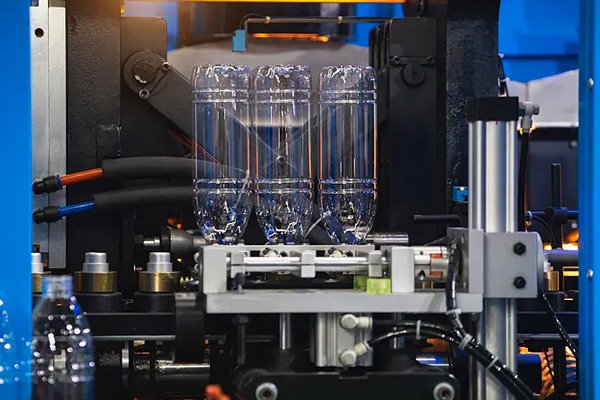

The efficiency and precision of bottle handling in a water bottle machine heavily depend on the performance of its feeding and discharging mechanisms. Traditional systems often struggle with misalignment when processing bottles of varying sizes, shapes, and heights, leading to jamming or improper transfers. To address this, an advanced automatic adjustment control system has been developed, integrating vision recognition, PLC control, and servo-driven mechanisms to ensure seamless bottle transfer during the cleaning process.

Structural Principles

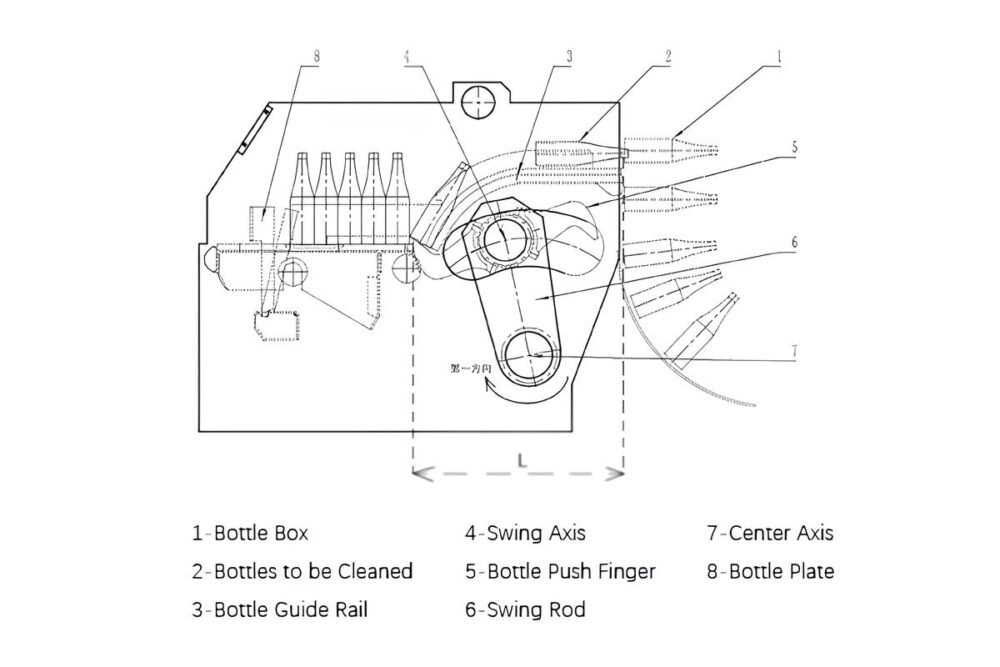

1. Bottle Feeding Mechanism

The feeding mechanism, located at the front end of the washing machine, consists of:

-

Input Conveyor Belt – Transports bottles into the washing chamber.

-

Alignment Plates – Positioned on both sides of the conveyor to arrange bottles in an orderly manner.

-

Pushing Fingers – Driven by a swing arm, these fingers transfer bottles from the conveyor into the carrier boxes.

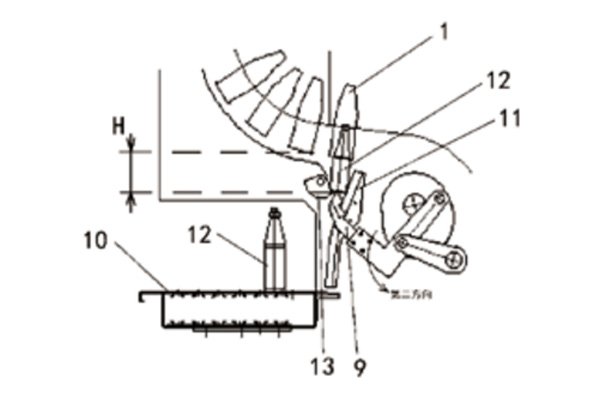

2. Bottle Discharging Mechanism

After cleaning, the bottles move to the discharging mechanism, which includes:

-

Drive Cam – Controls the periodic motion of bottle-catching fingers.

-

Sector Wheel – Rotates clockwise to guide cleaned bottles onto the discharge conveyor.

-

Discharge Guide Rail – Ensures smooth bottle transfer to the next production stage.

Automatic Adjustment Control System

To prevent misalignment (such as early or delayed pushing), the system employs:

1. Vision Recognition Module

-

Captures real-time bottle images to detect size, shape, and position.

-

Provides data for PLC-based compensation calculations.

2. PLC Control Module

-

Processes encoder signals and camera data to determine adjustment values.

-

Sends corrective commands to servo motors for precise alignment.

3. Conveyor Chain Detection System

-

Uses encoders to track carrier box positions, ensuring synchronization.

4. Servo-Driven Feeding/Discharging Mechanism

-

Adjusts pushing and catching fingers dynamically based on PLC feedback.

5. HMI (Human-Machine Interface)

-

Allows operators to monitor adjustments, modify settings, and restore default positions.

Control Process & Key Functions

1. Signal Acquisition & Processing

-

Encoders on each carrier box send pulse signals to the PLC.

-

The system calculates bottle flow positions and determines compensation needs.

2. Dynamic Compensation & Alignment

-

The PLC computes offset angles and adjusts servo motors accordingly.

-

Ensures smooth bottle transfer regardless of bottle specifications.

3. Auto-Recovery Function

-

Stores compensation values for different bottle types.

-

Enables one-click reset to predefined zero positions for quick changeovers.

The automatic adjustment control system significantly enhances the adaptability of the water bottle machine, reducing jamming and misalignment issues.

Have questions about packaging machines or need a custom line? Contact Sokos Machinery for free expert advice and tailored solutions.